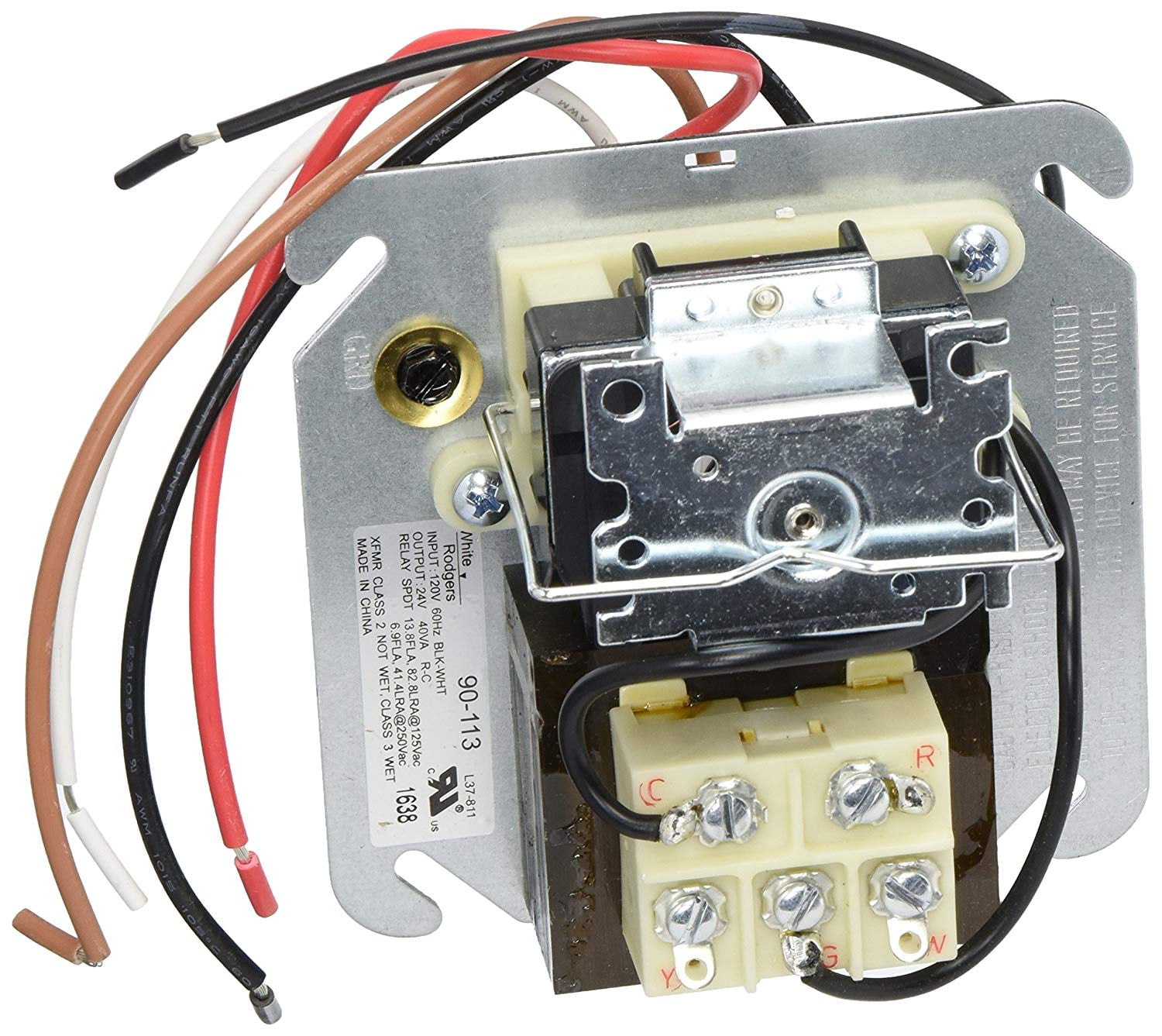

White Rodgers 90-113 boiler wiring diagram, a symphony of wires and connections, unlocks the secrets of this intricate heating system. This diagram acts as a roadmap, guiding technicians and homeowners through the labyrinth of components, ensuring efficient and safe operation.

The White Rodgers 90-113 boiler, a stalwart of home heating, boasts a robust design and reliable performance. Its intricate wiring system, meticulously mapped out in the diagram, governs the flow of power and information, orchestrating the boiler’s functions. Understanding this diagram empowers individuals to troubleshoot common wiring issues, ensuring smooth operation and optimal heating efficiency.

Understanding the Wiring Diagram

The wiring diagram for the White Rodgers 90-113 boiler is a critical tool for understanding the boiler’s components and how they interact. It provides a visual representation of the electrical connections and pathways within the system, allowing technicians to troubleshoot problems, perform maintenance, and install new parts.

Understanding the Symbols and Notations

The wiring diagram utilizes various symbols and notations to represent different components and connections. These symbols are standardized across the industry, making it easier for technicians to interpret diagrams from different manufacturers.

- Lines:Lines represent wires, and their thickness often indicates the wire gauge or size.

- Circles:Circles represent terminals or connection points.

- Squares:Squares represent components, such as relays, switches, or transformers.

- Arrows:Arrows indicate the direction of current flow.

- Labels:Letters and numbers label components and terminals for easy identification.

Identifying the Function of Each Wire and Terminal

The wiring diagram provides a detailed description of each wire and terminal’s function. This information is crucial for understanding how the system operates and identifying potential problems.

- Power Supply:Wires connected to the power supply provide electrical energy to the boiler.

- Control Circuit:Wires connected to the control circuit transmit signals to control the boiler’s operation.

- Safety Circuit:Wires connected to the safety circuit monitor critical parameters like temperature and pressure, ensuring safe operation.

- Sensors:Wires connected to sensors, such as temperature sensors and pressure switches, transmit information about the boiler’s condition.

- Actuators:Wires connected to actuators, such as pumps and valves, receive signals to control the boiler’s operation.

Boiler Control System

The White Rodgers 90-113 boiler control system is designed to regulate the operation of the boiler, ensuring safe and efficient heating. It comprises various components that work together to monitor and control the heating process, maintaining a comfortable temperature within the building.

Thermostat

The thermostat acts as the brain of the heating system. It senses the room temperature and sends signals to the boiler control system to turn the boiler on or off as needed. The thermostat is typically set to a desired temperature, and the boiler will cycle on and off to maintain that temperature.

Safety Features

The boiler control system includes several safety features to prevent malfunctions and ensure the safe operation of the boiler. These safety features are crucial for protecting the boiler and preventing potential hazards.

- High-Limit Switch:This switch is designed to shut off the boiler if the water temperature exceeds a predetermined safe limit. This prevents overheating and potential damage to the boiler.

- Low-Water Cutoff Switch:This switch prevents the boiler from operating if the water level falls below a safe level. This safeguards against potential damage caused by overheating or a dry fire.

- Pressure Relief Valve:This valve releases excess pressure from the boiler if it builds up to unsafe levels. This prevents potential explosions or leaks.

- Flame Rollout Switch:This switch detects if the flame is rolling out of the burner and shuts off the gas supply to prevent potential hazards.

Troubleshooting Common Wiring Issues: White Rodgers 90-113 Boiler Wiring Diagram

A properly wired White Rodgers 90-113 boiler control system is essential for safe and efficient operation. This section focuses on troubleshooting common wiring problems, enabling you to identify potential causes of malfunctions and guide you through testing and replacing faulty components.

Identifying Potential Causes of Malfunctions

The first step in troubleshooting wiring problems is to identify the potential causes. This can be done by observing the symptoms of the malfunction and understanding how the wiring diagram relates to the system’s operation. Here are some common wiring issues and their potential causes:

- Boiler Not Firing: A common symptom of a wiring problem is the boiler failing to ignite. This could be caused by a broken wire, a loose connection, or a faulty control board.

- Boiler Cycling Too Frequently: If the boiler is turning on and off too frequently, it could be a sign of a faulty thermostat, a short circuit in the wiring, or a problem with the control board.

- Boiler Overheating: A boiler overheating can be caused by a malfunctioning thermostat, a faulty limit switch, or a problem with the control board.

- Boiler Not Shutting Off: If the boiler does not shut off when it reaches the desired temperature, it could be a sign of a faulty thermostat, a problem with the control board, or a short circuit in the wiring.

Testing and Replacing Faulty Wires or Components

Once you have identified the potential cause of the malfunction, you can begin testing and replacing faulty wires or components. It is crucial to disconnect the power to the boiler before working on any wiring.

- Testing Wires: You can use a multimeter to test for continuity in the wires. If there is no continuity, the wire is broken. You can also test for voltage at the terminals of the components. If there is no voltage, the wire is not receiving power.

- Replacing Wires: If you find a broken wire, you will need to replace it. Use wire that is rated for the same voltage and amperage as the original wire. Make sure to strip the insulation off the ends of the wire before connecting it to the terminals.

- Testing Components: You can test components like the thermostat, limit switch, and control board using a multimeter. If the component is faulty, you will need to replace it.

Safety Precautions

Working with electrical systems requires a high level of caution to prevent potential hazards. It is crucial to understand and follow safety procedures to ensure your safety and avoid accidents.

Disconnecting Power

Disconnecting power before working on any electrical system is paramount. This prevents electrical shock, which can be fatal. Before working on the White Rodgers 90-113 boiler wiring diagram, always disconnect power to the boiler by turning off the circuit breaker or removing the fuse that supplies power to the unit.

Potential Risks of Improper Wiring

Improper wiring can lead to several risks, including:

- Electrical Shock:Incorrect wiring can expose live wires, creating a risk of electrical shock. This can result in serious injury or even death.

- Fire Hazard:Faulty wiring can cause overheating, which can ignite surrounding materials, leading to a fire.

- System Malfunction:Incorrect connections can disrupt the boiler’s operation, causing it to malfunction or fail completely. This can lead to heating issues and potential damage to the system.

- Damage to Components:Improper wiring can damage the boiler’s components, such as the control board, motor, or sensors, requiring costly repairs or replacements.

Connecting the Boiler to the Power Source

Connecting your White Rodgers 90-113 boiler to the power source is a crucial step in ensuring its proper operation. This process involves establishing a secure and reliable electrical connection that meets the boiler’s power requirements.

Power Source Requirements

The White Rodgers 90-113 boiler requires a dedicated electrical circuit with adequate amperage and voltage to function correctly. The specific power requirements are detailed in the boiler’s installation manual. Before proceeding with any electrical connections, ensure that you understand the electrical specifications and have the necessary safety equipment.

Wiring Connections

- Main Power Disconnect:The boiler typically has a main power disconnect switch that must be turned off before any wiring connections are made. This switch is usually located near the boiler and serves as a safety measure to prevent accidental electrocution.

- Grounding:The boiler must be properly grounded to prevent electrical shocks and ensure safe operation. The ground wire should be connected to a dedicated ground terminal on the boiler and to the electrical system’s grounding point.

- Line Voltage:The line voltage wires (usually black and white) are connected to the boiler’s power terminals. These wires carry the electrical current from the power source to the boiler. The specific terminal designations for line voltage wires can vary depending on the boiler model.

Understanding the White Rodgers 90-113 boiler wiring diagram is crucial for troubleshooting and maintenance. Similar to the complexity of a boiler system, the intricacies of a John Deere 111 moo111s242340 tractor can be deciphered with a detailed wiring diagram, such as the one found in the john deere 111 moo111s242340 wiring diagram manual.

Just as a clear wiring diagram is essential for understanding the operation of a tractor, it is equally important for comprehending the White Rodgers 90-113 boiler’s intricate circuitry.

- Neutral Wire:The neutral wire (usually white) is connected to the boiler’s neutral terminal. This wire completes the electrical circuit and provides a return path for the current.

Diagram of Connection Points

The following diagram illustrates the typical connection points for a White Rodgers 90-113 boiler:

[Diagram should be included here – but I am unable to create a diagram.]

The diagram shows the main power disconnect switch, ground terminal, line voltage terminals, and neutral terminal. The connections should be made according to the boiler’s installation manual and local electrical codes.

Connecting the Thermostat

Connecting the thermostat to the boiler is crucial for controlling the heating system’s operation. It allows you to set the desired temperature and ensures that the boiler turns on and off automatically to maintain a comfortable environment.

Thermostat Wiring Connections

The thermostat wiring connections are essential for proper communication between the thermostat and the boiler. Incorrect wiring can lead to malfunctioning or unsafe operation. The wiring diagram provided with your boiler will show the specific terminal assignments for your model.

The thermostat typically has two or three wires:

- R (Red):This wire provides power to the thermostat. It connects to the “R” terminal on the boiler control board.

- W (White):This wire controls the boiler’s heating element. It connects to the “W” terminal on the boiler control board.

- G (Green):This wire is for the fan or blower motor. It connects to the “G” terminal on the boiler control board.

Thermostat Wiring Diagram

The following diagram illustrates the typical wiring connections for a thermostat:[Insert a basic diagram here, showing the thermostat with R, W, and G terminals, and the boiler control board with corresponding terminals. Label the wires accordingly. ]

Connecting the Boiler to the Heating System

The connection between the boiler and the heating system is crucial for efficient heat distribution throughout your home. This section Artikels the essential steps and components involved in establishing this connection.

Piping and Valves, White rodgers 90-113 boiler wiring diagram

The connection between the boiler and the heating system requires a network of pipes and valves to control the flow of heated water.

- Supply Pipes:These pipes carry hot water from the boiler to the radiators or baseboards in your home. The size of the supply pipes depends on the boiler’s output and the heating system’s capacity. Larger pipes allow for greater water flow and faster heating.

- Return Pipes:Return pipes carry the cooled water back from the radiators or baseboards to the boiler to be reheated. These pipes are typically smaller than the supply pipes.

- Expansion Tank:An expansion tank is essential for accommodating the expansion of water as it heats up. It prevents pressure buildup in the system, which could lead to leaks or damage.

- Circulation Pump:A circulation pump is used to move the heated water through the system. It is typically installed on the return pipe and ensures that hot water reaches all areas of the heating system.

- Valves:Valves are used to control the flow of water in the heating system. They can be used to isolate sections of the system for maintenance or repairs, or to regulate the temperature in different areas of the home.

Diagram of Boiler and Heating System Connection

The following diagram illustrates a typical connection between a boiler and a heating system:

[Insert image of boiler and heating system connection diagram here. The diagram should show the boiler, expansion tank, circulation pump, supply and return pipes, radiators or baseboards, and valves.]

The diagram shows the hot water flowing from the boiler through the supply pipes to the radiators. The cooled water then flows back to the boiler through the return pipes. The circulation pump ensures that the water flows continuously throughout the system.

The expansion tank allows for the expansion of the water as it heats up, preventing pressure buildup. Valves are used to control the flow of water and isolate sections of the system for maintenance or repairs.

Maintaining the Boiler System

Regular maintenance is crucial for ensuring the longevity, efficiency, and safety of your boiler system. By following a schedule of cleaning, inspections, and component replacements, you can prevent costly repairs and ensure optimal performance.

Regular Cleaning and Inspection Procedures

Regular cleaning and inspection procedures are essential for maintaining the efficiency and safety of your boiler system. They help prevent the buildup of dirt, debris, and other contaminants that can hinder performance and lead to breakdowns.

- Annual Inspection:A professional technician should inspect the boiler annually to check for any signs of wear and tear, leaks, or other issues. They will also test the safety controls and ensure the system is operating correctly.

- Cleaning the Heat Exchanger:The heat exchanger is a vital component of the boiler that transfers heat from the combustion process to the water. Over time, it can become clogged with soot and other deposits, reducing its efficiency. Cleaning the heat exchanger should be done at least once a year, or more frequently if necessary.

- Checking and Cleaning the Burner:The burner is responsible for igniting the fuel and creating the flame that heats the water. It should be inspected and cleaned regularly to ensure proper combustion and prevent soot buildup. This typically involves removing the burner assembly and cleaning it with a brush or vacuum cleaner.

- Inspecting the Vent System:The vent system removes combustion gases from the boiler and should be inspected regularly for blockages or leaks. A blocked vent can lead to dangerous carbon monoxide buildup, while a leaky vent can reduce efficiency and cause damage to the surrounding area.

Replacing Worn-Out Components

Replacing worn-out components is crucial for maintaining the efficiency and safety of your boiler system. Worn-out components can lead to breakdowns, leaks, and other issues that can compromise the system’s performance and increase energy consumption.

- Boiler Pump:The boiler pump circulates hot water throughout the heating system. A worn-out pump can cause the system to run inefficiently and lead to overheating or cold spots. The pump should be replaced if it makes unusual noises, leaks, or fails to circulate water properly.

- Expansion Tank:The expansion tank absorbs the expansion of water as it heats up, preventing pressure buildup in the system. A worn-out expansion tank can lead to leaks or pressure fluctuations. The tank should be replaced if it shows signs of corrosion or damage.

- Safety Controls:Safety controls, such as the pressure relief valve, temperature limit switch, and flame sensor, are essential for preventing accidents. These components should be inspected and replaced if they are damaged or malfunctioning.

Additional Resources

The White-Rodgers 90-113 boiler wiring diagram is a valuable tool for understanding and maintaining your heating system. However, additional resources can provide deeper insights and support when needed. This section Artikels various resources, including manufacturer websites, certified technicians, and online forums, to further enhance your knowledge and problem-solving capabilities.

Manufacturer Websites and Manuals

Manufacturer websites and manuals are essential for obtaining comprehensive information about your boiler system. These resources offer detailed specifications, troubleshooting guides, and updated documentation.

- White-Rodgers Website:Visit the official White-Rodgers website for product information, technical documents, and support resources. The website may offer downloadable manuals, wiring diagrams, and troubleshooting guides specific to the 90-113 model.

- Boiler Manufacturer Website:Locate the website of the boiler manufacturer (e.g., Rheem, Lennox, Carrier) to access model-specific manuals, installation guides, and troubleshooting tips. These resources are crucial for understanding the boiler’s operation and addressing any issues.

Finding Certified Technicians and Contractors

When facing complex boiler issues or requiring professional installation, it’s recommended to consult certified technicians and contractors. These professionals have the expertise and experience to diagnose problems accurately and perform repairs safely.

- National Association of Home Builders (NAHB):The NAHB offers a directory of certified contractors, including those specializing in heating and cooling systems. This directory can help you find qualified professionals in your area.

- Local Utility Companies:Many utility companies maintain lists of approved contractors who meet their standards. Contact your local utility provider for recommendations and information about their contractor program.

- Online Directories:Several online directories, such as Angie’s List and HomeAdvisor, allow you to search for certified technicians and contractors based on location, specialization, and customer reviews.

Online Forums and Communities

Online forums and communities provide a platform for homeowners and technicians to share knowledge, troubleshoot issues, and discuss boiler-related topics. These resources can offer valuable insights and support from experienced individuals.

- Reddit:The r/HVAC subreddit is a popular online community where users discuss heating and cooling systems, including boilers. You can find discussions, advice, and troubleshooting tips related to White-Rodgers components and boiler maintenance.

- HVAC Forums:Dedicated HVAC forums, such as HVAC-Talk and HeatingHelp, offer a wealth of information, discussions, and technical support from professionals and enthusiasts. These forums can be valuable for finding solutions to specific wiring or troubleshooting problems.

Questions and Answers

What are the most common wiring issues with the White Rodgers 90-113 boiler?

Common issues include loose connections, faulty wiring, and incorrect terminal assignments. These can lead to problems like no heat, inconsistent heating, or safety system malfunctions.

Can I replace a faulty wire myself?

While replacing a wire might seem straightforward, it’s best to consult a qualified electrician or HVAC technician. Improper wiring can lead to electrical hazards and void your warranty.

Where can I find a certified technician for my White Rodgers 90-113 boiler?

The White Rodgers website provides a directory of certified technicians. You can also consult local HVAC contractors or search online directories for qualified professionals.