Sure bail bilge switch wiring diagram is a crucial aspect of a boat’s electrical system, ensuring proper operation and safety. This diagram guides the flow of electricity from the battery to the bilge pump, which removes water from the boat’s hull.

Understanding this diagram is essential for boat owners, allowing them to troubleshoot problems, perform maintenance, and ensure the smooth operation of their boat.

The bilge switch is a vital safety component, preventing water from accumulating in the bilge and potentially causing damage to the boat. It acts as a control switch, allowing the pump to activate when water levels rise, effectively removing the water and maintaining the boat’s stability.

This guide will delve into the intricacies of the bilge switch wiring diagram, explaining its components, functionality, and importance in maintaining a safe and reliable boating experience.

Bilge Switch Wiring Diagram: Sure Bail Bilge Switch Wiring Diagram

A bilge switch is an essential safety component in a boat’s electrical system, designed to activate a bilge pump when water accumulates in the bilge. It acts as a manual override for the automatic bilge pump, allowing the boat owner to manually pump out water in case of a leak or flooding.The purpose of a bilge switch is to provide a reliable way to remove water from the bilge, preventing the boat from sinking.

It is typically wired to a bilge pump, which pumps water out of the boat’s bilge. The bilge switch acts as a trigger, allowing the boat owner to activate the pump when needed.

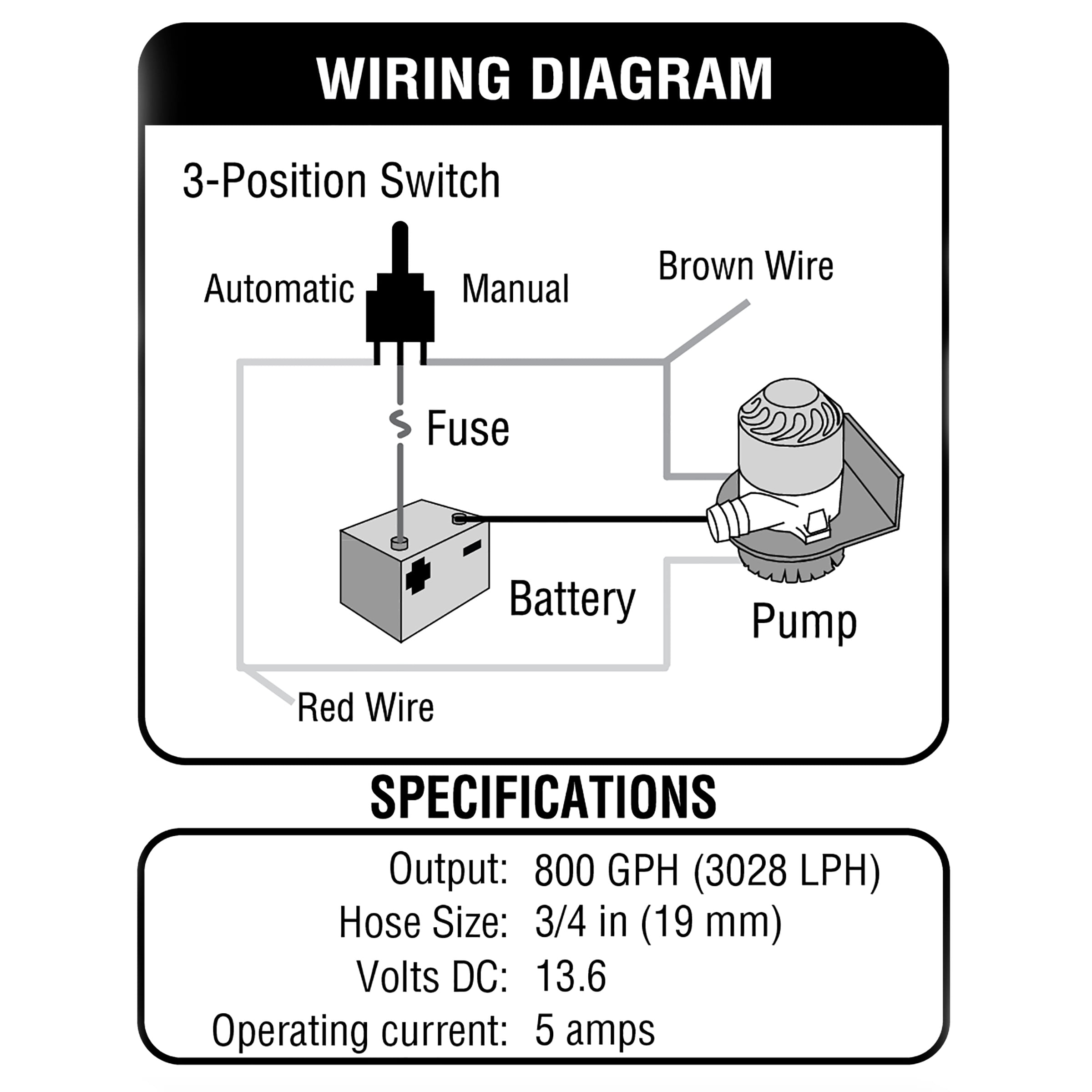

Bilge Switch Wiring Diagram Components

A basic bilge switch wiring diagram consists of several key components:

- Bilge switch: This is the main component that allows the boat owner to manually activate the bilge pump.

- Bilge pump: This is the device that pumps water out of the bilge.

- Wires: These connect the bilge switch to the bilge pump and to the boat’s electrical system.

- Fuse: This protects the wiring and the bilge pump from overloads.

- Battery: This provides the power for the bilge pump.

The bilge switch wiring diagram is essential for understanding how the bilge switch and pump are connected and how they function. It helps boat owners troubleshoot problems and ensure the proper operation of the bilge system.

Troubleshooting Bilge Switch Wiring

A malfunctioning bilge switch can be a serious problem, potentially leading to water accumulation in the bilge and damage to your boat. This section will guide you through the process of troubleshooting common bilge switch wiring issues.

Identifying Potential Causes

A malfunctioning bilge switch can result from various issues, including faulty wiring, blown fuses, or a damaged bilge pump. Understanding the potential causes helps in pinpointing the root of the problem.

- Faulty Wiring:Damaged or corroded wires can interrupt the electrical flow to the bilge switch, preventing it from functioning correctly. This is a common issue, especially in marine environments where wires are exposed to moisture and salt.

- Blown Fuses:Fuses are designed to protect electrical circuits from overloads. If a fuse blows, it interrupts the circuit, preventing further damage. A blown fuse can be a sign of a short circuit or an overloaded circuit, which may be related to the bilge switch wiring.

- Damaged Bilge Pump:A faulty bilge pump can also cause the bilge switch to malfunction. A damaged pump may not be able to draw water out of the bilge, leading to the bilge switch activating continuously. Additionally, a malfunctioning pump may draw excessive current, potentially blowing a fuse or damaging the wiring.

Troubleshooting Process

A systematic approach is essential for effectively troubleshooting bilge switch wiring issues. This process involves a series of steps to isolate the problem and determine the cause.

- Inspect the Bilge Switch:Begin by visually inspecting the bilge switch for any signs of damage, corrosion, or loose connections. Ensure the switch is securely mounted and that the contacts are clean and free of debris. Check the switch’s operation by manually activating it and observing if it clicks or makes any unusual noises.

- Check the Wiring:Inspect the wiring leading to and from the bilge switch for any signs of damage, fraying, or corrosion. Trace the wires to ensure they are properly connected to the switch, the bilge pump, and the power source. If any damage is found, repair or replace the affected wires.

- Test the Fuse:Locate the fuse associated with the bilge switch and check its condition. A blown fuse will have a broken filament or a gap in the metal strip. Replace the fuse with a new one of the same amperage rating.

- Test the Bilge Pump:If the wiring and fuse are in good condition, test the bilge pump by directly connecting it to a power source. If the pump operates, the issue is likely with the bilge switch or its wiring. If the pump does not operate, it needs to be replaced.

Safety Considerations

Working with electrical systems on a boat requires a high level of caution and adherence to safety protocols. Improper wiring or handling of electrical components can lead to serious consequences, including electrical shocks, fires, and even explosions.

Safe Operation and Maintenance of Bilge Switches

Safe operation and maintenance of bilge switches are crucial for ensuring the safety of the boat and its occupants.

- Always disconnect the power supply to the bilge pump and switch before working on them.This is essential to prevent accidental electric shocks.

- Inspect the bilge switch and wiring regularly for signs of damage or wear.Look for frayed wires, loose connections, or corrosion. Replace any damaged components immediately.

- Use the appropriate tools and equipment when working with electrical systems.Never use tools or equipment that are not designed for electrical work.

- Ensure that all electrical connections are properly secured.Loose connections can lead to overheating and fires.

- Keep the bilge area clean and dry.Moisture and debris can cause electrical shorts and fires.

- Avoid using extension cords for bilge pumps.Extension cords can overheat and pose a fire hazard.

- Do not overload the electrical system.Make sure that the total amperage of all devices connected to the system does not exceed the system’s capacity.

“Never work on electrical systems while the boat is running or while the power supply is connected.”

Understanding the sure bail bilge switch wiring diagram can be a bit like deciphering an ancient map, but once you’ve mastered the basics, it’s all about following the flow. Similarly, if you’re trying to troubleshoot a faulty gas gauge on an old GS 750 Suzuki, a clear diagram like the one found on this website can be a lifesaver.

Once you’ve navigated the intricacies of the gas gauge, you’ll be able to apply the same logic to tackle the intricacies of the bilge switch wiring diagram.

Installation and Maintenance

Installing a bilge switch wiring system is a crucial step in ensuring the safety and functionality of your boat. Proper installation and regular maintenance are essential for preventing potential hazards and ensuring reliable operation.

Installation Steps

Installing a bilge switch wiring system requires careful planning and execution. The following steps Artikel the process:

- Determine the location for the bilge switch.The switch should be easily accessible and in a location that is not prone to water damage.

- Select the appropriate wiring.Use marine-grade wiring that is rated for the amperage of the bilge pump.

- Run the wiring from the bilge pump to the switch.Route the wiring through protective conduits or cable ties to prevent chafing or damage.

- Connect the wiring to the bilge pump and switch.Ensure proper polarity and secure connections using marine-grade terminals.

- Test the system.Turn on the switch and check that the bilge pump is functioning correctly.

Wiring Techniques and Connections

Proper wiring techniques are essential for ensuring the safety and reliability of the bilge switch system. Here are some key considerations:

- Use marine-grade wiring and connectors.These components are designed to withstand the harsh marine environment and prevent corrosion.

- Route the wiring through protective conduits or cable ties.This helps prevent chafing and damage to the wiring.

- Ensure proper polarity.Connect the positive (+) wire to the positive (+) terminal and the negative (-) wire to the negative (-) terminal.

- Secure connections using marine-grade terminals.This ensures reliable electrical contact and prevents corrosion.

Maintenance and Inspection, Sure bail bilge switch wiring diagram

Regular maintenance and inspection of the bilge switch wiring system are crucial for ensuring its functionality and preventing potential hazards. Here are some important maintenance practices:

- Visually inspect the wiring for any signs of damage or corrosion.This includes checking the wiring, terminals, and switch.

- Test the switch and bilge pump regularly.Ensure that the switch is operating properly and that the bilge pump is functioning correctly.

- Clean the terminals and connections.This helps prevent corrosion and ensures reliable electrical contact.

- Replace any damaged or corroded wiring or components.This ensures the safety and reliability of the system.

Common Bilge Switch Wiring Issues

Bilge switch wiring, while seemingly simple, can be prone to issues that can compromise the safety and functionality of your boat. Understanding these issues and knowing how to troubleshoot them is crucial for maintaining a safe and reliable bilge pump system.

Short Circuits

Short circuits occur when an electrical current takes an unintended path, bypassing the intended circuit. This can happen in bilge switch wiring due to:

- Damaged insulation:Deterioration of wire insulation due to age, heat, or abrasion can expose the wire’s conductor, creating a path for current to flow to unintended locations. This can cause a short circuit and even lead to a fire.

- Loose connections:Loose connections in the wiring can lead to increased resistance and heat buildup. Over time, this heat can damage the insulation and create a short circuit.

- Water intrusion:Water can cause a short circuit by bridging the gap between the wire conductors. This is a particular concern in bilge pump systems as they are exposed to water.

Troubleshooting Tips:

- Visually inspect the wiring for any signs of damage, such as frayed or exposed wires, or corrosion.

- Check the connections at the switch, pump, and fuse box for tightness. Loose connections should be tightened.

- If water intrusion is suspected, disconnect the power to the system and dry the affected areas thoroughly.

Consequences of Neglecting:

- Fire hazard:A short circuit can cause significant heat buildup, potentially igniting nearby materials.

- System failure:A short circuit can disrupt the flow of current, preventing the bilge pump from functioning properly.

Alternative Bilge Switch Designs

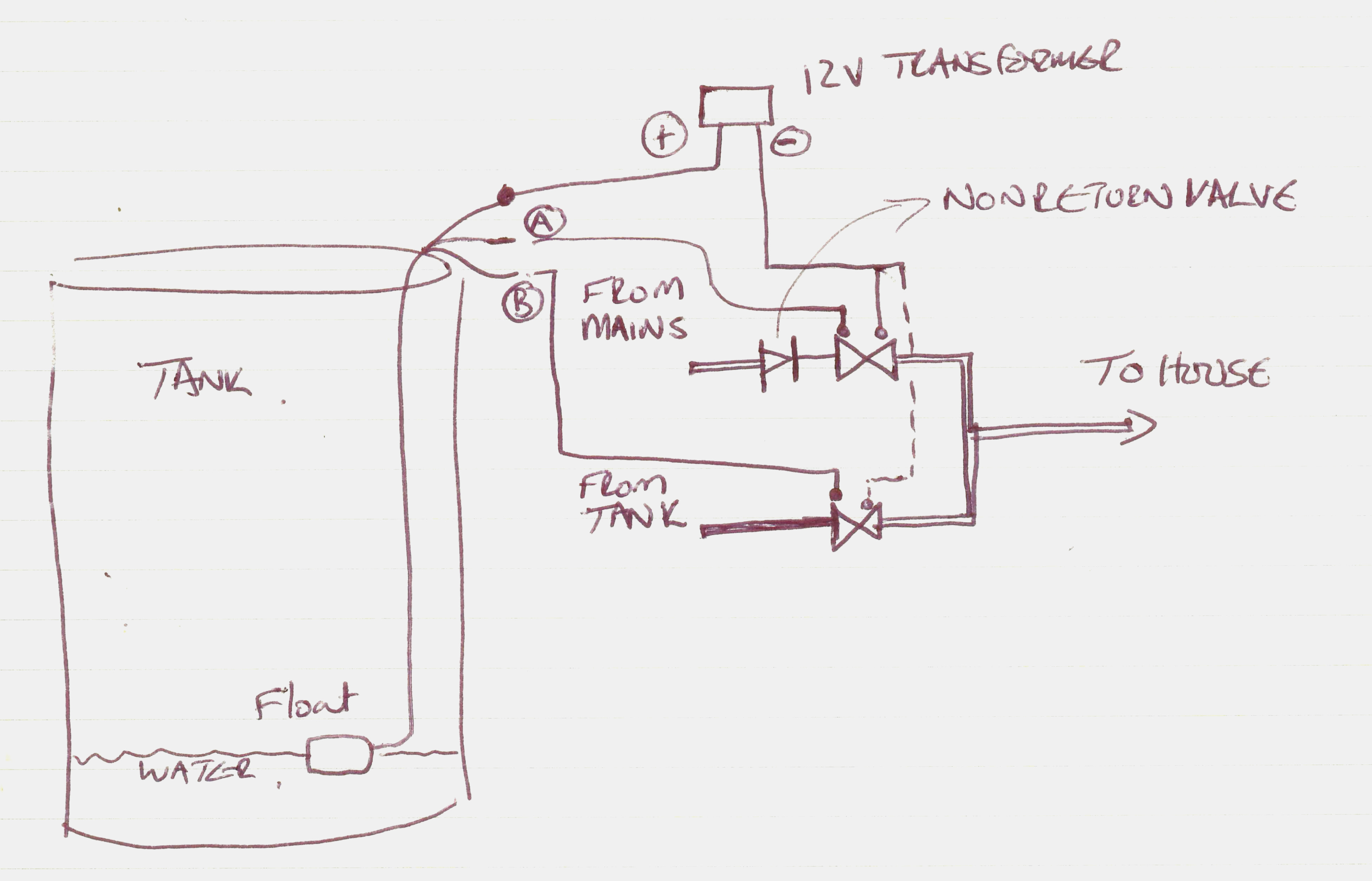

Bilge switch designs have evolved beyond the traditional manual switch. Modern technology offers alternative designs that automate the bilge pump activation, enhancing safety and convenience. These alternative designs leverage sensors and electronics to detect water levels and trigger the pump automatically.

Automatic Bilge Pumps with Built-in Sensors

Automatic bilge pumps are equipped with built-in sensors that detect water levels in the bilge. When the water level reaches a predetermined threshold, the pump activates automatically, removing the water without requiring manual intervention. These pumps typically employ float switches or pressure sensors to detect water levels.

Advantages

- Automatic Operation:Eliminates the need for manual intervention, ensuring the pump operates when needed, even when the vessel is unattended.

- Increased Safety:Continuous monitoring of water levels minimizes the risk of flooding and damage, especially during unattended periods.

- Reduced Maintenance:Automatic pumps require less frequent maintenance compared to manual pumps, as they are constantly monitoring the bilge.

Disadvantages

- Higher Cost:Automatic bilge pumps are generally more expensive than manual pumps due to the integrated sensors and electronics.

- Potential for Malfunction:Like any electronic device, automatic pumps are susceptible to malfunctions, which could lead to pump failure or false activation.

- Power Consumption:Automatic pumps require a constant power supply, which can drain batteries if not properly managed.

Suitability

Automatic bilge pumps with built-in sensors are ideal for vessels that are frequently unattended, such as sailboats or vessels used for extended periods. They offer peace of mind by automatically removing water, minimizing the risk of flooding. However, it’s essential to consider the potential for malfunctions and ensure proper power management to prevent battery drain.

High-Water Alarm Systems

High-water alarm systems are designed to alert the operator of rising water levels in the bilge. They typically use float switches or pressure sensors to detect water levels and trigger an audible or visual alarm. These systems do not automatically activate the bilge pump but provide early warning of potential flooding.

Advantages

- Early Warning:High-water alarms provide timely alerts, allowing the operator to address the issue before it becomes critical.

- Cost-Effective:These systems are generally less expensive than automatic bilge pumps, making them a viable option for budget-conscious boat owners.

- Flexibility:High-water alarm systems can be integrated with various bilge pump configurations, providing a customizable solution.

Disadvantages

- Manual Intervention Required:High-water alarms only alert the operator, requiring manual activation of the bilge pump to remove water.

- Potential for False Alarms:False alarms can occur due to sensor malfunctions or minor water ingress, leading to unnecessary concern.

- Limited Functionality:These systems only provide an alert, not automatic water removal, which might not be sufficient in certain situations.

Suitability

High-water alarm systems are suitable for vessels that are frequently monitored by the operator. They provide early warning of potential flooding, allowing for timely intervention. However, they require manual pump activation, making them less effective for unattended vessels or situations where immediate water removal is crucial.

Remote Bilge Pump Control Systems

Remote bilge pump control systems allow the operator to monitor and control the bilge pump from a remote location. These systems typically use wireless technology to transmit data and commands between the pump and a remote control unit.

Advantages

- Remote Monitoring and Control:Operators can monitor water levels and activate the pump from a distance, providing greater flexibility and control.

- Increased Safety:Remote control systems allow operators to address bilge issues even when not physically present on the vessel.

- Integration with Other Systems:Remote bilge pump control systems can be integrated with other onboard systems, such as GPS or navigation equipment.

Disadvantages

- Higher Cost:Remote bilge pump control systems are typically more expensive than traditional manual or automatic systems.

- Potential for Signal Interference:Wireless signals can be susceptible to interference, potentially disrupting communication between the pump and the remote control unit.

- Battery Consumption:Remote control systems require a power source for both the pump and the remote control unit, which can drain batteries if not properly managed.

Suitability

Remote bilge pump control systems are suitable for vessels where remote monitoring and control are desirable, such as large vessels or vessels used for extended periods. They provide operators with greater flexibility and control over the bilge pump, enhancing safety and convenience.

However, it’s essential to consider the potential for signal interference and ensure proper power management to avoid battery drain.

Resources and References

Seeking further information on bilge switch wiring diagrams can enhance your understanding and ensure safe and efficient operation of your boat’s bilge system. Several resources are available for boat owners, electricians, and marine professionals.

Reputable Online Resources

A plethora of online resources offer valuable information on bilge switch wiring diagrams. These resources often provide comprehensive guides, step-by-step instructions, and troubleshooting tips.

- BoatUS:This organization provides a wealth of information on boating, including electrical systems. Their website features articles, videos, and forums dedicated to boat maintenance and repair.

- West Marine:A leading marine retailer, West Marine offers a vast library of articles and resources on boat electrical systems. They cover various topics, including bilge pump wiring, troubleshooting, and safety considerations.

- Marine Electrical Systems:This website is a comprehensive resource for marine electrical systems. It provides detailed information on bilge pump wiring, troubleshooting, and common issues.

- Boat Owners Association of The United States (BoatUS):BoatUS provides a wide range of information on boating, including electrical systems. Their website features articles, videos, and forums dedicated to boat maintenance and repair.

- National Marine Electronics Association (NMEA):NMEA is a non-profit organization that sets standards for marine electronics. Their website provides resources on marine electrical systems, including bilge pump wiring.

Relevant Books

Books on marine electrical systems offer in-depth knowledge and practical guidance on bilge switch wiring.

- “The Complete Idiot’s Guide to Boat Electrical Systems” by John C. Payne:This book provides a comprehensive overview of marine electrical systems, including bilge pump wiring, troubleshooting, and maintenance.

- “Boat Electrical Systems: A Practical Guide” by Charles Wing:This book offers a practical approach to understanding and working with marine electrical systems. It includes detailed information on bilge pump wiring, troubleshooting, and safety considerations.

- “Marine Electrical Systems Handbook” by Nigel Calder:This comprehensive handbook covers all aspects of marine electrical systems, including bilge pump wiring, troubleshooting, and installation.

Articles and Forums

Numerous articles and forums dedicated to boating and marine electrical systems can provide valuable insights and practical advice on bilge switch wiring.

- “Boat Electrical Systems” articles on Practical Sailor:Practical Sailor is a respected marine magazine that publishes articles on various aspects of boating, including electrical systems. Their website features a comprehensive archive of articles on bilge pump wiring, troubleshooting, and maintenance.

- “Marine Electrical” forum on The Boat Forum:The Boat Forum is a popular online community for boat owners and enthusiasts. Their “Marine Electrical” forum provides a platform for discussions and advice on bilge pump wiring, troubleshooting, and common issues.

- “Bilge Pump Wiring” articles on YachtForums:YachtForums is a dedicated forum for yacht owners and enthusiasts. Their website features articles and discussions on bilge pump wiring, troubleshooting, and safety considerations.

Expert Answers

How often should I check my bilge switch wiring?

It’s recommended to inspect your bilge switch wiring at least once a year or more frequently if your boat is used often. Look for signs of corrosion, loose connections, or damaged insulation.

What is the difference between a float switch and a manual switch?

A float switch automatically activates the bilge pump when water levels rise, while a manual switch requires the boat owner to manually turn on the pump.

Can I use a standard car battery for my bilge pump?

While it’s possible, it’s not recommended. Boat batteries are designed to handle the demands of marine electrical systems and are typically more robust than car batteries.

What should I do if my bilge pump isn’t working?

First, check the fuse and make sure it’s not blown. Then, inspect the wiring for any loose connections or damage. If the wiring is intact, the problem might be with the pump itself.