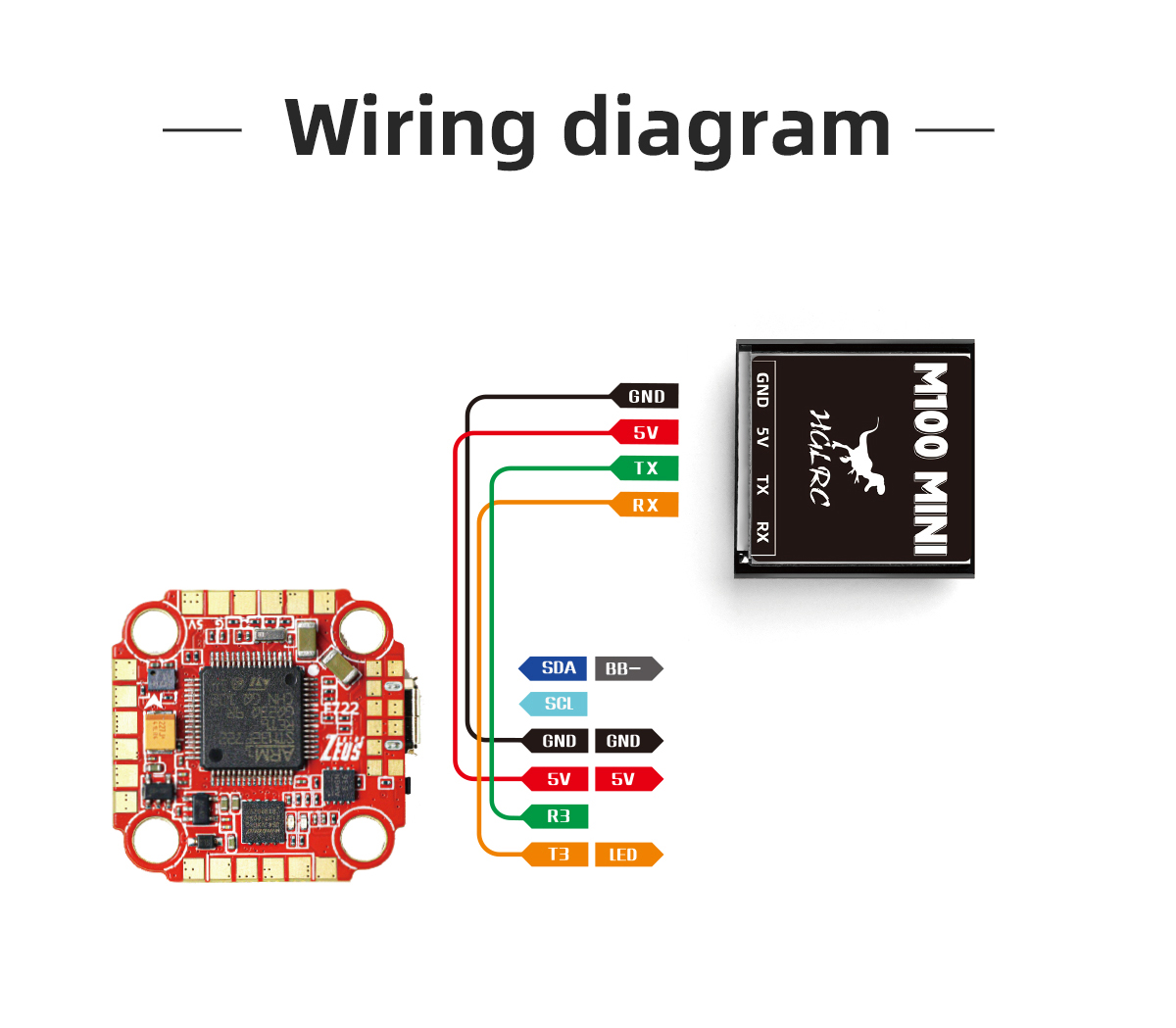

The M100 VGPS wiring diagram is a critical document for understanding the intricate connections and functionalities of this advanced system. It serves as a blueprint, guiding technicians and engineers through the complex network of components, sensors, and communication interfaces that make up the M100 VGPS.

This diagram is essential for installation, troubleshooting, maintenance, and even for exploring future advancements in VGPS technology.

This comprehensive guide delves into the intricacies of the M100 VGPS wiring diagram, starting with a basic understanding of its purpose and structure. We’ll explore the key components, their functions, and how they interact within the system. You’ll learn to interpret the diagram, identify potential issues, and even troubleshoot common problems.

We’ll also discuss safety considerations, alternative wiring configurations, and the integration of the M100 VGPS with other systems. By the end of this guide, you’ll have a thorough grasp of the M100 VGPS wiring diagram and its vital role in the operation and maintenance of this sophisticated technology.

M100 VGPS Overview

The M100 VGPS (Vehicle Guidance and Positioning System) is a cutting-edge technology designed to enhance vehicle safety, efficiency, and overall performance. This system seamlessly integrates advanced navigation, positioning, and communication technologies to provide real-time guidance and information to drivers and fleet managers.The M100 VGPS system plays a crucial role in various industries, including transportation, logistics, and construction.

Its primary purpose is to optimize vehicle operations, reduce accidents, and improve fuel efficiency, ultimately leading to cost savings and increased productivity.

Key Components of the M100 VGPS System

The M100 VGPS system consists of several key components that work together to provide comprehensive guidance and positioning capabilities. These components include:

- GPS Receiver:The GPS receiver is responsible for receiving signals from GPS satellites to determine the vehicle’s precise location. It uses triangulation to calculate the vehicle’s latitude, longitude, and altitude.

- IMU (Inertial Measurement Unit):The IMU is a sensor that measures the vehicle’s acceleration, angular velocity, and heading. It provides accurate and real-time information about the vehicle’s motion, even in areas with limited GPS coverage.

- Communication Module:The communication module enables the M100 VGPS system to communicate with other devices and systems. It uses various communication protocols, such as cellular networks, Wi-Fi, and Bluetooth, to exchange data.

- Display Unit:The display unit provides drivers with essential information, including navigation instructions, speed limits, and warnings. It typically features a high-resolution screen and intuitive user interface.

- Software Platform:The software platform is the brain of the M100 VGPS system. It processes data from various sensors, analyzes information, and provides real-time guidance and alerts to drivers and fleet managers.

Applications and Benefits of Using an M100 VGPS System

The M100 VGPS system offers a wide range of applications and benefits across various industries. Here are some key advantages of using this system:

- Enhanced Safety:The M100 VGPS system provides real-time alerts for potential hazards, such as blind spots, lane departures, and approaching traffic. It also helps drivers navigate complex intersections and avoid accidents.

- Improved Efficiency:By providing optimal routes and minimizing delays, the M100 VGPS system helps drivers maximize their efficiency. It also enables fleet managers to monitor vehicle performance and optimize resource allocation.

- Reduced Fuel Consumption:The system’s advanced navigation features help drivers avoid unnecessary idling and optimize driving routes, leading to significant fuel savings.

- Enhanced Fleet Management:The M100 VGPS system allows fleet managers to track their vehicles in real-time, monitor driver behavior, and analyze performance data. This information helps them optimize fleet operations and improve overall efficiency.

- Real-Time Communication:The communication module enables drivers and fleet managers to stay connected, allowing for quick and efficient communication in case of emergencies or other critical situations.

The M100 VGPS system is a valuable asset for businesses looking to enhance safety, efficiency, and productivity. Its advanced features and real-time data capabilities empower drivers and fleet managers to make informed decisions and optimize vehicle operations.

VGPS Wiring Diagram Basics

A wiring diagram is a visual representation of the electrical connections within a system, such as the M100 VGPS. It is essential for understanding the flow of electricity, troubleshooting issues, and performing maintenance. These diagrams use standardized symbols and conventions to depict the various components and their interconnections.

Symbols and Conventions

Wiring diagrams use standardized symbols to represent different electrical components, such as wires, connectors, switches, and sensors. These symbols are designed to be universally understood, making it easier for technicians to interpret and work with wiring diagrams. Some common symbols used in VGPS wiring diagrams include:

- Wires:Solid lines represent wires, with different colors indicating different circuits or functions.

- Connectors:These are depicted as circles or rectangles, with pins numbered for identification.

- Switches:These are represented by various symbols depending on their type, such as toggle switches, push buttons, or rotary switches.

- Sensors:Symbols vary based on the sensor type, such as temperature sensors, pressure sensors, or position sensors.

- Ground:A ground symbol represents the reference point for electrical circuits, typically denoted by a triangle with a horizontal line at the bottom.

VGPS Wiring Diagram Structure

The M100 VGPS wiring diagram is structured to provide a clear and organized representation of the electrical connections. It typically includes the following sections:

- Component List:This section lists all the components included in the system, with their corresponding reference designations.

- Schematic Diagram:This is the main part of the diagram, showing the electrical connections between components. It is often presented in a hierarchical manner, with different levels of detail for different parts of the system.

- Pin Assignments:This section provides detailed information on the pin assignments for connectors, including the function of each pin.

- Cable Routing:This section shows the physical routing of cables and harnesses within the system, including the connection points and cable lengths.

M100 VGPS Wiring Diagram Components

The M100 VGPS wiring diagram is a complex network of interconnected components, each playing a crucial role in the system’s functionality. Understanding the function and interconnection of these components is essential for troubleshooting, maintenance, and system optimization.

Power Supply

The power supply unit provides the necessary electrical energy to power the various components of the M100 VGPS. It typically receives input from a standard AC power source and converts it to the appropriate DC voltage required by the system.

The power supply unit may also include features such as over-voltage protection, over-current protection, and short-circuit protection to ensure the safety and stability of the system.

Sensors

Sensors are responsible for collecting data about the physical environment or the system’s operation. In the M100 VGPS, sensors may include:

- GPS Receiver:Acquires satellite signals to determine the vehicle’s position, speed, and direction.

- Accelerometer:Measures acceleration forces acting on the vehicle, providing information about vehicle movement and potential impacts.

- Gyroscope:Measures the vehicle’s angular velocity, providing information about the vehicle’s rotation and orientation.

- Temperature Sensors:Monitor the temperature of critical components, such as the battery or the control unit, to prevent overheating.

- Pressure Sensors:Monitor tire pressure or other pressure-related parameters within the vehicle.

Control Units

Control units process the data received from sensors, execute predefined algorithms, and control the actuators. The M100 VGPS typically includes:

- Main Control Unit (MCU):The central processing unit that coordinates the overall operation of the system. It receives data from sensors, performs calculations, and sends commands to actuators.

- GPS Processor:Processes the raw data from the GPS receiver, calculates the vehicle’s position, speed, and direction, and sends this information to the MCU.

- Communication Module:Handles the communication between the VGPS and other systems, such as the vehicle’s CAN bus, cellular networks, or satellite networks.

Communication Interfaces, M100 vgps wiring diagram

Communication interfaces enable the M100 VGPS to exchange data with other systems. These interfaces may include:

- CAN Bus:A common communication protocol used in automotive systems, allowing the VGPS to communicate with other vehicle components.

- Cellular Modem:Enables wireless communication with a server or cloud platform, allowing for data transmission, remote monitoring, and software updates.

- Satellite Modem:Enables communication with a satellite network, providing connectivity in areas where cellular networks are unavailable.

Connections Between Components

The components of the M100 VGPS are interconnected through a network of wires and connectors. The wiring diagram illustrates these connections and their significance in the system’s operation.

The connections between components ensure the flow of data and control signals, allowing the system to function as intended. For example, the GPS receiver sends its data to the GPS processor, which then transmits the processed information to the MCU. The MCU, in turn, sends commands to the actuators based on the received data and the pre-programmed algorithms.

The wiring diagram also provides information about the power supply connections, grounding points, and the use of fuses and relays for protection and safety. Understanding these connections is essential for troubleshooting any issues that may arise within the system.

Safety Considerations

Working with electrical systems requires a high level of caution and adherence to safety practices to prevent accidents and injuries. Proper handling of components and wiring is crucial, as incorrect connections can lead to electrical hazards. This section Artikels essential safety precautions and potential risks associated with VGPS wiring.

Electrical Safety Precautions

It is crucial to prioritize safety when working with electrical systems. Here are some essential precautions:

- Always disconnect power to the VGPS system before working on it.

- Use insulated tools to handle electrical components.

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure the work area is dry and free of clutter.

- Never work on electrical systems while standing on wet surfaces.

- Avoid touching exposed wires or terminals.

- Be aware of potential hazards, such as live wires and exposed components.

Potential Hazards of Incorrect Wiring

Incorrect wiring can lead to various electrical hazards, including:

- Short circuits:These occur when there is an unintended path for current to flow, often due to exposed wires or faulty connections. This can lead to excessive heat, fire, and damage to equipment.

- Overloads:If the wiring is not properly sized for the current load, it can overheat and cause a fire. Overloads can occur when too many devices are connected to a circuit or when a device draws more current than the wiring can handle.

- Electrocution:This is a serious hazard that can occur when a person comes into contact with live wires or exposed terminals. It can lead to severe injury or death.

- Equipment damage:Incorrect wiring can damage equipment by causing voltage surges, short circuits, or other electrical problems.

Preventing Electrical Hazards

To prevent electrical hazards, it is essential to:

- Use the correct wiring:Refer to the M100 VGPS wiring diagram and use the appropriate wire sizes and types.

- Ensure all connections are secure:Loose connections can lead to short circuits and other problems.

- Inspect wiring regularly:Look for signs of damage, wear, or overheating. Replace any damaged wiring immediately.

- Use proper grounding techniques:Grounding helps to prevent electrical shocks and equipment damage.

- Follow all manufacturer’s instructions:The manufacturer’s instructions provide specific guidance on how to safely install and operate the VGPS system.

Remember:Safety should always be the top priority when working with electrical systems. If you are not comfortable working with electricity, consult a qualified electrician.

Alternative Wiring Configurations

The M100 VGPS offers flexibility in its wiring configurations, allowing for customization to suit specific application requirements. This section explores various wiring options, their advantages and disadvantages, and how to adapt the wiring diagram for different scenarios.

Alternative Wiring Configurations for M100 VGPS

The M100 VGPS can be wired in various configurations to meet specific needs. These configurations involve changes in the connection points and wiring paths, potentially impacting performance, functionality, and safety.

Direct Wiring

Direct wiring is the most straightforward configuration, connecting the VGPS directly to the power source and load. This eliminates the need for intermediate components, minimizing wiring complexity and potential points of failure. However, direct wiring may not be suitable for applications requiring isolation, protection, or control.

Relay-Based Wiring

Relay-based wiring introduces a relay to control the power flow to the load. This configuration allows for remote control of the VGPS, enabling switching and isolation. Relays provide protection against overcurrents and short circuits, enhancing system reliability. However, relay-based wiring adds complexity and potential failure points due to the relay itself.

Solid-State Relay (SSR) Wiring

Solid-state relays (SSRs) replace electromechanical relays, offering advantages in speed, reliability, and longevity. SSRs are electronically controlled, eliminating mechanical wear and tear. This configuration provides fast switching speeds, precise control, and improved resistance to environmental factors. However, SSRs can be more expensive than traditional relays, and their operation requires careful consideration of voltage and current ratings.

Remote Sensing Wiring

Remote sensing wiring allows the VGPS to monitor voltage and current at the load, regardless of the distance. This configuration improves accuracy by compensating for voltage drops in the wiring. Remote sensing is particularly beneficial for long wiring runs or applications with significant voltage fluctuations.

However, it requires additional wiring and can increase complexity.

Fuse-Protected Wiring

Fuse-protected wiring incorporates fuses to protect the VGPS and load from overcurrents. Fuses act as safety devices, interrupting the circuit if the current exceeds a predetermined limit. This configuration enhances safety and prevents damage to the VGPS and connected equipment.

However, fuses require regular inspection and replacement, and they can introduce an additional failure point.

Adapting the Wiring Diagram

Adapting the M100 VGPS wiring diagram for specific application requirements involves understanding the function of each component and how they interact. The following steps Artikel the process:

1. Identify the application’s specific needs

Determine the voltage, current, control requirements, and any special considerations.

2. Select the appropriate wiring configuration

Choose the configuration that best aligns with the application’s needs, considering factors like complexity, cost, and performance.

3. Modify the wiring diagram

Figuring out the M100 VGPS wiring diagram can be a real head-scratcher, but it’s all about tracing those wires and understanding how they connect. If you’re into classic American vehicles, you might find the 1984 Chevy G10 van cluster wiring diagram interesting too, as it’s similar in some ways to the M100.

Once you get the hang of it, you’ll be able to navigate the M100 wiring like a pro.

Adjust the connection points, wiring paths, and components based on the selected configuration.

4. Verify the modified wiring diagram

Ensure the modified diagram meets safety standards and provides the desired functionality.

Example: Adapting for Remote Control

For an application requiring remote control, the wiring diagram can be adapted by incorporating a relay. The relay’s coil can be connected to a remote control signal, while its contacts connect to the VGPS output. This configuration allows the VGPS to be switched on and off remotely.

Example: Adapting for Overcurrent Protection

To incorporate overcurrent protection, fuses can be added to the wiring diagram. Fuses should be rated appropriately for the VGPS’s current rating and the load’s expected current draw. The fuses should be placed in the circuit’s positive line, protecting the VGPS and load from overcurrents.

Maintenance and Repair: M100 Vgps Wiring Diagram

Maintaining the M100 VGPS system involves regular inspections and proactive measures to ensure optimal performance and prevent potential issues. Repairing the system requires a systematic approach, focusing on identifying the fault, troubleshooting, and implementing corrective actions.

Routine Maintenance

Routine maintenance of the M100 VGPS system is crucial for ensuring its longevity and reliable operation. The following guidelines provide a comprehensive approach to preventative maintenance:

- Visual Inspection:Regularly inspect the VGPS system for any signs of damage, corrosion, or loose connections. This includes examining cables, connectors, and mounting points.

- Component Testing:Periodically test the functionality of key components such as the GPS receiver, antenna, and power supply. This can involve running diagnostic tests or checking signal strength.

- Environmental Considerations:Ensure the VGPS system is operating within its specified environmental limits, including temperature, humidity, and vibration. This may involve adjustments to the installation or the use of protective measures.

- Software Updates:Regularly update the VGPS software to incorporate bug fixes, performance enhancements, and new features.

- Cleaning:Keep the VGPS system clean and free of dust and debris. This can involve using compressed air or a soft brush.

Common Repair Procedures

Repairing the M100 VGPS system involves diagnosing the issue, isolating the faulty component, and implementing the necessary repair. The following procedures address common repair scenarios:

- Cable Inspection and Replacement:If a cable is damaged or shows signs of wear, it should be replaced. This involves identifying the cable type, sourcing a replacement, and carefully disconnecting and reconnecting the cables.

- Connector Repair:Loose or damaged connectors can be repaired by cleaning the contacts, tightening screws, or replacing the connector.

- Component Replacement:If a component fails, it should be replaced with a compatible part. This may involve desoldering the old component and soldering in the new one.

- Software Troubleshooting:Software issues can be resolved by updating the software, reinstalling the software, or contacting the manufacturer for technical support.

Documentation of Wiring Modifications

Properly documenting any wiring modifications is essential for maintaining the integrity of the M100 VGPS system and facilitating future repairs. The following best practices ensure effective documentation:

- Modification Log:Maintain a detailed log of all wiring modifications, including the date, description of the change, and the reason for the modification.

- Wiring Diagrams:Update the wiring diagrams to reflect any changes made to the system. This ensures that future technicians have accurate information about the wiring configuration.

- Component Labels:Clearly label all components and wires to facilitate identification and troubleshooting.

- Photos:Take photos of the system before and after modifications to provide visual documentation of the changes.

Integration with Other Systems

The M100 VGPS system is designed for seamless integration with other systems and devices, enhancing its functionality and providing a comprehensive solution for various applications. This integration enables data sharing, control, and synchronization between different components, optimizing overall performance and efficiency.

The integration process involves establishing communication pathways and protocols between the M100 VGPS and other systems. This typically involves defining the data exchange format, setting up communication channels, and ensuring compatibility between the different systems.

Types of Integration

The M100 VGPS can integrate with various systems, including:

- Building Management Systems (BMS):The VGPS can be integrated with BMS to provide real-time location data for building occupants and assets, enabling optimized space utilization, security, and emergency response. The integration involves transmitting location data from the VGPS to the BMS via protocols like BACnet or Modbus.

- Fleet Management Systems (FMS):Integrating the VGPS with FMS allows for tracking and monitoring vehicles and assets in real-time, improving fleet efficiency, reducing operational costs, and enhancing safety. The integration involves transmitting location data from the VGPS to the FMS via protocols like GPS or cellular networks.

- Security Systems:The VGPS can be integrated with security systems to enhance security measures by providing location data for access control, intrusion detection, and emergency response. The integration involves transmitting location data from the VGPS to the security system via protocols like RS-485 or Ethernet.

- Data Analytics Platforms:The VGPS can be integrated with data analytics platforms to leverage location data for generating insights, optimizing operations, and making data-driven decisions. The integration involves transmitting location data from the VGPS to the analytics platform via APIs or data streams.

Communication Protocols

The M100 VGPS supports various communication protocols for seamless integration with other systems:

- RS-485:A robust serial communication protocol commonly used in industrial applications, suitable for integrating the VGPS with devices like sensors, actuators, and control systems.

- Ethernet:A high-speed networking protocol, allowing the VGPS to connect to networks and communicate with other devices, such as servers, computers, and cloud-based platforms.

- Wi-Fi:A wireless networking protocol, enabling the VGPS to connect to wireless networks and communicate with other devices, including smartphones, tablets, and laptops.

- Cellular Networks:The VGPS can connect to cellular networks to transmit location data to remote servers or applications, enabling real-time tracking and monitoring.

Challenges and Solutions

Integrating the M100 VGPS with other systems can present some challenges:

- Compatibility:Ensuring compatibility between the VGPS and the target system’s communication protocols and data formats is crucial. Solutions include using compatible communication modules, adapting data formats, or employing middleware to bridge the gap.

- Security:Protecting sensitive location data during transmission and storage is essential. Solutions include using encryption protocols, secure communication channels, and implementing access control measures.

- Scalability:Integrating the VGPS with large-scale systems may require considerations for scalability and performance. Solutions include using distributed architectures, load balancing techniques, and optimizing data processing.

Future Trends in VGPS Technology

The field of VGPS technology is constantly evolving, with new advancements emerging that promise to revolutionize the way we design, implement, and manage complex electrical systems. These advancements are driven by a confluence of factors, including the increasing demand for efficiency, reliability, and safety in various industries.

This section explores the future trends in VGPS technology and their impact on wiring diagrams.

Advancements in Components

Advancements in components are expected to significantly impact VGPS technology. These advancements will lead to smaller, more efficient, and more reliable components, ultimately impacting the complexity and design of wiring diagrams.

- Miniaturization:The trend towards miniaturization in electronic components will continue to impact VGPS technology. Smaller components will allow for more compact and efficient designs, reducing the overall size and weight of electrical systems. This miniaturization will also lead to a higher density of components within a given space, requiring more intricate wiring diagrams to accommodate the increased complexity.

- Increased Efficiency:Advancements in semiconductor technology will lead to more efficient components with lower power consumption. This will reduce the heat generated by the system, leading to improved reliability and lifespan. The increased efficiency of components will also impact the design of power distribution systems, potentially simplifying wiring diagrams by reducing the need for bulky transformers and other power management components.

- Improved Reliability:The use of more robust materials and advanced manufacturing processes will lead to more reliable components. This will contribute to the overall reliability of electrical systems, reducing the frequency of failures and maintenance requirements. Improved reliability will also simplify the design of wiring diagrams, as the need for redundant components and backup systems may be reduced.

Advancements in Communication Protocols

Advancements in communication protocols are expected to revolutionize the way VGPS systems are designed, implemented, and monitored. These advancements will enable faster data transfer rates, increased network capacity, and enhanced security features.

- High-Speed Data Transfer:The adoption of high-speed communication protocols, such as Ethernet and fiber optic, will enable faster data transfer rates. This will facilitate real-time monitoring and control of VGPS systems, allowing for more responsive and efficient operation. Faster data transfer rates will also impact the design of wiring diagrams, requiring more complex network infrastructure to support the increased bandwidth demands.

- Increased Network Capacity:The development of advanced network technologies will enable the creation of larger and more complex VGPS networks. This will allow for the integration of a wider range of devices and systems, enabling more comprehensive monitoring and control capabilities. The increased network capacity will necessitate more complex wiring diagrams to accommodate the expanded network infrastructure.

- Enhanced Security Features:Advancements in cybersecurity will lead to more secure communication protocols, protecting VGPS systems from cyberattacks. These security features will be crucial for ensuring the integrity and reliability of critical infrastructure. Enhanced security features may also impact the design of wiring diagrams, requiring additional layers of security protocols and access control mechanisms.

Advancements in System Architecture

Advancements in system architecture are expected to lead to more modular, scalable, and adaptable VGPS systems. These advancements will enable the seamless integration of different components and subsystems, creating more flexible and customizable solutions.

- Modular Design:The adoption of modular design principles will allow for the easy replacement and upgrade of individual components within a VGPS system. This will simplify maintenance and repair operations, reducing downtime and improving overall system reliability. Modular design will also impact the design of wiring diagrams, requiring more flexible and adaptable wiring configurations to accommodate the interchangeable nature of components.

- Scalability:The ability to scale VGPS systems to meet changing demands will be crucial for future applications. Scalable systems will allow for the addition of new components and subsystems without disrupting existing operations. Scalability will also impact the design of wiring diagrams, requiring flexible and adaptable wiring configurations that can accommodate future expansions.

- Adaptability:The need for adaptable VGPS systems that can respond to changing conditions will become increasingly important. Adaptable systems will be able to adjust their operation in response to changes in the environment, user demands, or system performance. Adaptability will also impact the design of wiring diagrams, requiring more flexible and reconfigurable wiring configurations to support the dynamic nature of these systems.

Impact on Wiring Diagrams

The advancements discussed above will significantly impact the interpretation and use of VGPS wiring diagrams.

- Increased Complexity:The miniaturization of components, the adoption of high-speed communication protocols, and the integration of more complex systems will lead to more complex wiring diagrams. These diagrams will require a higher level of detail and accuracy to accurately represent the interconnectedness of components within a VGPS system.

- Greater Emphasis on Data:Wiring diagrams will increasingly incorporate data-driven information, such as component specifications, communication protocols, and system performance metrics. This will enable a more comprehensive understanding of the VGPS system and facilitate more effective troubleshooting and maintenance operations.

- Use of Digital Tools:The use of digital tools for creating, managing, and interpreting wiring diagrams will become increasingly prevalent. These tools will offer enhanced capabilities for visualization, analysis, and collaboration, improving the efficiency and effectiveness of VGPS system design and maintenance.

Expert Answers

What are the different types of connectors used in the M100 VGPS wiring diagram?

The M100 VGPS wiring diagram uses a variety of connectors, including RJ-45, DB-9, and terminal blocks, depending on the specific component and its function.

What are the typical voltage and current ratings for the M100 VGPS system?

The voltage and current ratings for the M100 VGPS system vary depending on the specific components and their power requirements. Consult the system’s documentation or manufacturer’s specifications for detailed information.

How often should I perform routine maintenance on the M100 VGPS system?

Routine maintenance for the M100 VGPS system should be performed according to the manufacturer’s recommendations, which may vary depending on the operating environment and usage patterns.

Where can I find additional resources for learning more about the M100 VGPS system?

You can find additional resources for learning more about the M100 VGPS system from the manufacturer’s website, online forums, and technical publications.