Bmw 328xi vacuume diagram – BMW 328xi vacuum diagram is your key to understanding the intricate air system that keeps your car running smoothly. This diagram acts as a roadmap, guiding you through the network of vacuum lines, pumps, and actuators that control everything from braking to climate control.

Imagine a complex web of pipes and hoses that connect various components, all working in unison to deliver the necessary air pressure for different functions. The vacuum diagram visualizes this intricate system, revealing how each part contributes to the overall operation.

By understanding the vacuum diagram, you can troubleshoot potential problems, perform necessary maintenance, and ensure your BMW 328xi runs at peak performance.

Introduction

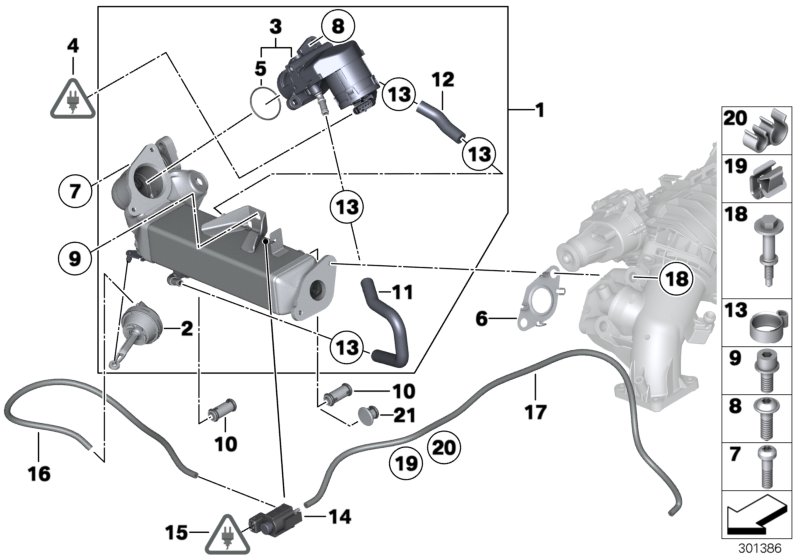

The BMW 328xi is a compact executive car known for its performance and handling. It is powered by a four-cylinder engine and features a sophisticated vacuum system that plays a crucial role in various vehicle functions. Understanding the operation of the vacuum system is essential for diagnosing and resolving potential issues.This vacuum diagram serves as a visual guide to the components and pathways of the vacuum system in the BMW 328xi.

It provides a detailed representation of how vacuum is generated, distributed, and utilized throughout the vehicle. By carefully studying this diagram, technicians can gain valuable insights into the functionality of the vacuum system, facilitating efficient troubleshooting and repairs.

Vacuum System Components

The vacuum system in the BMW 328xi consists of several essential components that work together to create and distribute vacuum throughout the vehicle. These components include:

- Vacuum Pump: The vacuum pump, typically driven by the engine, generates the vacuum needed for various functions.

- Vacuum Reservoir: The vacuum reservoir acts as a storage unit for vacuum, ensuring a consistent supply even when the engine is under load.

- Vacuum Lines: A network of vacuum lines, made of hoses or tubing, distributes vacuum to different components throughout the vehicle.

- Vacuum Actuators: Vacuum actuators are devices that use vacuum to perform specific functions, such as controlling the brake booster, HVAC system, or other systems.

Components of the Vacuum System: Bmw 328xi Vacuume Diagram

The vacuum system in the BMW 328xi plays a crucial role in various functions, including brake assist, power steering, and climate control. Understanding the components and their roles is essential for diagnosing and resolving issues related to these systems.

Finding a BMW 328xi vacuum diagram can be a real pain, right? I mean, you need to know where everything is connected to troubleshoot those pesky vacuum leaks. If you’re working on a 2012 Ford Focus, though, you can check out this 2012 Ford Focus power booster location diagram to get a visual on how the system works.

Once you’ve got a handle on that, you can apply the same logic to your BMW 328xi and get that vacuum system running smooth again.

Vacuum System Components

The vacuum system in the BMW 328xi consists of several key components, each with a specific function. These components work together to create and maintain the vacuum needed for various vehicle operations.

| Component Name | Function | Location |

|---|---|---|

| Vacuum Pump | Generates vacuum by converting mechanical energy into negative pressure. | Mounted on the engine, typically near the intake manifold. |

| Vacuum Lines | Transport vacuum from the pump to various actuators and components. | Run throughout the engine compartment and under the vehicle, connecting to different components. |

| Vacuum Reservoir | Stores vacuum, providing a reserve supply when demand exceeds the pump’s output. | Located near the vacuum pump or on the firewall. |

| Vacuum Actuators | Respond to changes in vacuum pressure to control various systems. | Located at different points in the vehicle, depending on the specific function. |

Vacuum System Operation

The vacuum system in the BMW 328xi plays a crucial role in controlling various engine and accessory functions. It operates by creating a partial vacuum within the system, which is then used to power various components.

Vacuum Generation and Distribution

The vacuum system relies on the engine’s intake manifold to generate vacuum. As the engine operates, the intake manifold creates a low-pressure area during the intake stroke, resulting in a vacuum. This vacuum is then distributed throughout the system using a network of vacuum lines.

Vacuum System Components

- Intake Manifold:The primary source of vacuum generation. It creates a low-pressure area during the intake stroke, drawing air into the engine cylinders.

- Vacuum Pump:In some applications, a dedicated vacuum pump may be used to supplement the intake manifold vacuum. This pump can provide additional vacuum for components requiring higher vacuum levels.

- Vacuum Lines:A network of hoses and tubes that distribute vacuum to various components throughout the engine compartment.

- Vacuum Reservoirs:Some systems may incorporate vacuum reservoirs to store and regulate vacuum pressure.

- Vacuum Actuators:Devices that use vacuum pressure to perform specific tasks, such as controlling the brake booster, HVAC system, or other functions.

Vacuum System Operation: A Step-by-Step Description

- Vacuum Generation:During the intake stroke of the engine, the intake manifold creates a low-pressure area (vacuum).

- Vacuum Distribution:The vacuum is then distributed through a network of vacuum lines to various components.

- Vacuum Actuator Operation:Vacuum actuators use the vacuum pressure to perform specific functions, such as:

- Brake Booster:Vacuum assists in amplifying the driver’s braking force.

- HVAC System:Vacuum may control the operation of the HVAC system’s actuators, such as the blend door or recirculation valve.

- Other Components:Vacuum may also be used to operate other components, such as the cruise control system or the fuel tank vent valve.

Vacuum Diagram Interpretation

A vacuum diagram is a visual representation of the vacuum system in a vehicle. It shows the various components, connections, and flow paths of vacuum within the system. Understanding the vacuum diagram is crucial for diagnosing and troubleshooting vacuum-related issues.

Vacuum Diagram Symbols and Lines

The vacuum diagram uses various symbols and lines to represent different components and their connections.

- Components:Each component in the vacuum system is represented by a specific symbol. Common symbols include:

- Vacuum Pump:A pump that creates vacuum within the system.

- Vacuum Reservoir:A container that stores vacuum for later use.

- Vacuum Actuator:A device that uses vacuum to perform a specific function, such as opening or closing a valve.

- Vacuum Switch:A switch that controls the flow of vacuum to different components.

- Vacuum Line:A hose or tube that carries vacuum from one component to another.

- Lines:The lines on the diagram represent the connections between different components. Different line types indicate different functions:

- Solid Lines:Indicate a direct connection between two components.

- Dashed Lines:Indicate a connection that is only active under certain conditions.

- Arrow Lines:Indicate the direction of vacuum flow.

Tracing Vacuum Flow

Tracing the flow of vacuum through the system is a fundamental step in understanding the vacuum diagram. This can be done by following the lines on the diagram, starting from the vacuum pump and following the path to the various components.

- Example:Consider a vacuum system with a vacuum pump, a vacuum reservoir, and a vacuum actuator. The diagram might show a solid line from the vacuum pump to the reservoir, and another solid line from the reservoir to the actuator.

This indicates that vacuum flows from the pump to the reservoir and then to the actuator.

Troubleshooting with the Vacuum Diagram

The vacuum diagram is an invaluable tool for diagnosing and troubleshooting vacuum-related issues. By analyzing the diagram, technicians can identify potential problems and pinpoint the source of the issue.

- Example:If a vacuum actuator is not working, the vacuum diagram can be used to check if the actuator is receiving vacuum. If the diagram shows a solid line from the vacuum reservoir to the actuator, and the reservoir is holding vacuum, then the problem likely lies with the actuator itself.

However, if the line is dashed, then the actuator may only receive vacuum under specific conditions, and the problem might be related to the switch or other component that controls the flow of vacuum to the actuator.

Common Vacuum System Problems

The vacuum system in a BMW 328xi, like in any car, is crucial for various functions, from power brakes to climate control. When the vacuum system malfunctions, it can lead to a range of issues, affecting the vehicle’s performance and safety.

Understanding common vacuum system problems and their causes can help diagnose and repair these issues effectively.

Vacuum Leaks

Vacuum leaks are a common problem that can occur in any vacuum system. Leaks can develop in various components, including hoses, connections, and even the vacuum pump itself. A vacuum leak can cause a variety of symptoms, including:

- Reduced brake assist

- Sluggish engine performance

- Erratic idle

- Problems with climate control

To diagnose a vacuum leak, a mechanic will often use a vacuum gauge to measure the vacuum pressure in the system. A low vacuum reading indicates a leak. The vacuum diagram can be used to pinpoint the location of the leak by tracing the vacuum lines and checking for any loose or damaged connections.

Repairing a vacuum leak typically involves replacing damaged hoses, tightening loose connections, or sealing any cracks or holes in the system. In some cases, the vacuum pump may need to be replaced.

Vacuum Pump Failure, Bmw 328xi vacuume diagram

The vacuum pump is responsible for creating the vacuum in the system. A failed vacuum pump can cause a variety of symptoms, including:

- Complete loss of brake assist

- Inability to start the engine

- No vacuum at all

A failed vacuum pump is usually diagnosed by checking the vacuum pressure in the system. If there is no vacuum, the pump is likely the culprit. The vacuum diagram can be used to verify the pump’s operation by tracing the vacuum lines from the pump to other components.

Repairing a failed vacuum pump typically involves replacing the pump. In some cases, the pump may be able to be rebuilt, but this is not always possible.

Vacuum Actuator Problems

Vacuum actuators are devices that use vacuum pressure to control various functions in the vehicle, such as the climate control system and the door locks. A faulty vacuum actuator can cause a variety of symptoms, including:

- Problems with climate control

- Door locks not working properly

- Other malfunctions related to the actuator’s function

Diagnosing a vacuum actuator problem usually involves checking the actuator’s operation. If the actuator is not working properly, it may need to be replaced. The vacuum diagram can be used to identify the actuator’s location and function.

Clogged Vacuum Lines

Vacuum lines can become clogged with debris, restricting the flow of vacuum pressure. This can cause a variety of symptoms, including:

- Reduced brake assist

- Sluggish engine performance

- Erratic idle

- Problems with climate control

To diagnose a clogged vacuum line, a mechanic will often use a vacuum gauge to measure the vacuum pressure in the system. A low vacuum reading may indicate a clogged line. The vacuum diagram can be used to trace the vacuum lines and identify any potential blockages.

Repairing a clogged vacuum line typically involves replacing the line or cleaning it out. In some cases, the line may need to be replaced with a new one.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting are essential to ensure the proper operation of the vacuum system in a BMW 328xi. By addressing potential issues early, you can prevent more serious problems and maintain optimal engine performance.

Recommended Maintenance Procedures

Performing routine maintenance on the vacuum system helps prevent problems and ensures its long-term reliability. Here are some recommended procedures:

- Inspect vacuum hoses for cracks, leaks, or deterioration:Over time, vacuum hoses can become brittle, cracked, or develop leaks due to exposure to heat, oil, and other environmental factors. Regularly inspecting these hoses and replacing any damaged ones is crucial to maintain proper vacuum pressure.

- Check vacuum system components for proper connections:Loose or disconnected vacuum lines can cause significant performance issues. Ensure all vacuum lines are securely connected to their respective components.

- Inspect vacuum pump for wear and tear:The vacuum pump is responsible for generating the vacuum needed for various engine functions. Inspect it for signs of wear, such as excessive noise or leaks.

- Replace vacuum system components as needed:Components like vacuum hoses, diaphragms, and check valves may need replacement over time due to wear or damage. Replace them with genuine BMW parts or equivalent high-quality alternatives.

Inspecting and Testing for Leaks

Identifying leaks in the vacuum system is crucial for diagnosing and resolving performance issues. Here’s how to inspect and test for leaks:

- Visual inspection:Carefully inspect all vacuum hoses for visible cracks, tears, or loose connections. Look for signs of oil or fluid leaks near vacuum system components.

- Listening for leaks:With the engine running, listen carefully for hissing sounds or air leaks around vacuum hoses and components.

- Smoke test:A smoke test involves introducing smoke into the vacuum system. This allows you to visually identify leaks by observing where the smoke escapes.

- Vacuum gauge test:Using a vacuum gauge, measure the vacuum pressure at different points in the system. A significant drop in vacuum pressure indicates a leak.

Using a Vacuum Gauge

A vacuum gauge is a valuable tool for diagnosing vacuum system issues. Here’s how to use it effectively:

- Connect the gauge:Connect the vacuum gauge to a vacuum port on the intake manifold or a vacuum line.

- Measure vacuum pressure:With the engine running at idle, observe the vacuum gauge reading.

- Interpret readings:A normal vacuum reading at idle is typically between 18 and 22 inches of mercury (inHg). A lower reading indicates a leak or other vacuum system problem.

- Test different points:Measure vacuum pressure at different points in the system to pinpoint the location of a leak.

Troubleshooting Common Vacuum System Problems

Common vacuum system problems can be diagnosed and addressed using a systematic approach. Here are some troubleshooting steps for common issues:

- Engine misfire or rough idle:A leak in the vacuum system can disrupt the airflow to the engine, causing misfires or a rough idle. Check vacuum hoses, diaphragms, and check valves for leaks.

- Poor fuel economy:A vacuum leak can lead to excessive fuel consumption. Inspect vacuum hoses and components for leaks.

- Engine power loss:A vacuum leak can reduce engine power. Check vacuum hoses, diaphragms, and check valves for leaks.

- Malfunctioning engine accessories:Some engine accessories, such as the brake booster, power steering pump, and climate control system, rely on vacuum. A vacuum leak can affect their operation. Inspect vacuum lines and components connected to these accessories.

Safety Considerations

Working with the vacuum system in a BMW 328xi requires careful attention to safety precautions to prevent injuries and damage to the vehicle.

Potential Hazards

Vacuum lines and components can pose several hazards if not handled properly.

- Exposure to hazardous materials:Vacuum lines can contain fluids such as brake fluid, power steering fluid, or coolant. These fluids can be harmful if they come into contact with skin or eyes. Always wear appropriate personal protective equipment (PPE), such as gloves and eye protection, when working with vacuum lines.

- Sharp edges and moving parts:Vacuum lines and components can have sharp edges that can cause cuts. Be cautious when handling these parts and wear gloves to protect your hands. Additionally, be aware of moving parts, such as the engine, that can cause injury if you are not careful.

- Fire hazards:Vacuum lines can be connected to components that operate at high temperatures, such as the intake manifold. Avoid contact with hot surfaces and be aware of potential fire hazards.

- Electrical hazards:Vacuum lines may be routed near electrical components. Be careful not to damage electrical wires or connectors when working with the vacuum system.

Safe Handling and Disposal

- Handle vacuum lines and components with care:Avoid bending or kinking vacuum lines, as this can restrict airflow. Use appropriate tools to disconnect and reconnect vacuum lines.

- Dispose of vacuum system parts properly:Dispose of vacuum lines and components in accordance with local regulations. Avoid throwing them in the trash or dumping them into the environment.

- Clean up spills immediately:If any fluids spill, clean them up immediately to prevent accidents.

- Inspect vacuum lines regularly:Regularly inspect vacuum lines for cracks, leaks, or damage. Replace damaged lines promptly to prevent problems.

Important Safety Tips

- Always disconnect the battery before working on the vacuum system.This will prevent accidental electrical shocks.

- Never work on the vacuum system while the engine is running.The engine creates a vacuum that can cause injury if you are not careful.

- Use a vacuum gauge to test the vacuum system.This will help you identify any leaks or problems.

- Consult the owner’s manual for specific safety instructions.

Answers to Common Questions

Where can I find a BMW 328xi vacuum diagram?

You can find a vacuum diagram in your BMW 328xi owner’s manual or online through reputable automotive resources like repair manuals or forums.

What are some common signs of a vacuum leak?

Common signs include rough idling, decreased engine power, a hissing sound, and malfunctioning vacuum-operated components like the brake booster.

How often should I check my vacuum system?

It’s a good idea to check your vacuum system during regular maintenance, especially if you notice any of the signs of a vacuum leak.