Understanding the 70 Coronet starter solenoid wiring diagram is crucial for any enthusiast or mechanic working on this classic car. The starter solenoid, a key component in the starting system, acts as an electrical relay, allowing the battery’s power to flow to the starter motor, initiating the engine’s rotation.

This guide will delve into the intricate details of the 70 Coronet starter solenoid wiring diagram, providing a comprehensive understanding of its components, operation, and troubleshooting methods.

From identifying the individual components and their corresponding wire colors to analyzing the flow of electricity through the circuit, this guide will equip you with the knowledge to diagnose and repair any starter solenoid issues. Whether you’re a seasoned mechanic or a novice DIY enthusiast, this resource will empower you to confidently tackle any starter solenoid-related challenges.

Introduction

The 1970 Dodge Coronet’s starter solenoid is a crucial component of the vehicle’s starting system. It acts as an electrical relay, connecting the battery’s power to the starter motor when the ignition key is turned. Understanding the wiring diagram for the starter solenoid is essential for troubleshooting starting problems and ensuring proper operation of the vehicle.

The Purpose and Function of the Starter Solenoid

The starter solenoid is responsible for completing the electrical circuit that allows the starter motor to crank the engine. When the ignition key is turned to the “start” position, the solenoid receives a signal from the ignition switch. This signal activates the solenoid, which closes a set of contacts, allowing a large current to flow from the battery to the starter motor.

The starter motor then begins to rotate, turning the engine crankshaft and starting the combustion process.

Identifying Components: 70 Coronet Starter Solenoid Wiring Diagram

The starter solenoid is a vital component in the starting system of a 1970 Chrysler Coronet. It acts as an electrical switch, connecting the battery to the starter motor when the ignition key is turned. Understanding the components and their functions is crucial for troubleshooting and repair.

Starter Solenoid Components, 70 coronet starter solenoid wiring diagram

The starter solenoid consists of several key components that work together to initiate the starting process. These components include:

- Solenoid Coil:This coil is an electromagnet that generates a magnetic field when energized. The magnetic field is responsible for pulling the armature towards the solenoid body.

- Armature:This is a movable iron core that is attracted to the solenoid coil when energized. The armature is connected to the starter motor and acts as a switch, completing the circuit to the starter motor.

- Contacts:These are electrical contacts that connect the battery to the starter motor when the armature is pulled towards the solenoid body. There are typically two main contacts: the battery contact and the starter motor contact.

- Terminal Posts:These are posts that connect the solenoid to the battery and the starter motor. There are typically four terminal posts: the battery terminal, the ignition terminal, the starter terminal, and the ground terminal.

Starter Solenoid Component Functions and Wire Colors

| Component | Function | Wire Color |

|---|---|---|

| Solenoid Coil | Generates a magnetic field when energized. | Red (Battery) |

| Armature | Acts as a switch, completing the circuit to the starter motor. | N/A |

| Battery Contact | Connects the battery to the starter motor. | Red (Battery) |

| Starter Motor Contact | Connects the starter motor to the battery. | Red (Battery) |

| Terminal Posts | Connect the solenoid to the battery and the starter motor. | Red (Battery), Yellow (Ignition), Purple (Starter), Black (Ground) |

Starter Solenoid Component Locations and Wire Colors

| Component | Location | Wire Color |

|---|---|---|

| Solenoid Coil | Inside the solenoid body. | Red (Battery) |

| Armature | Inside the solenoid body, attached to the starter motor. | N/A |

| Battery Contact | Located on the solenoid body, connected to the battery terminal post. | Red (Battery) |

| Starter Motor Contact | Located on the solenoid body, connected to the starter motor terminal post. | Red (Battery) |

| Terminal Posts | Located on the solenoid body. | Red (Battery), Yellow (Ignition), Purple (Starter), Black (Ground) |

Wiring Diagram Analysis

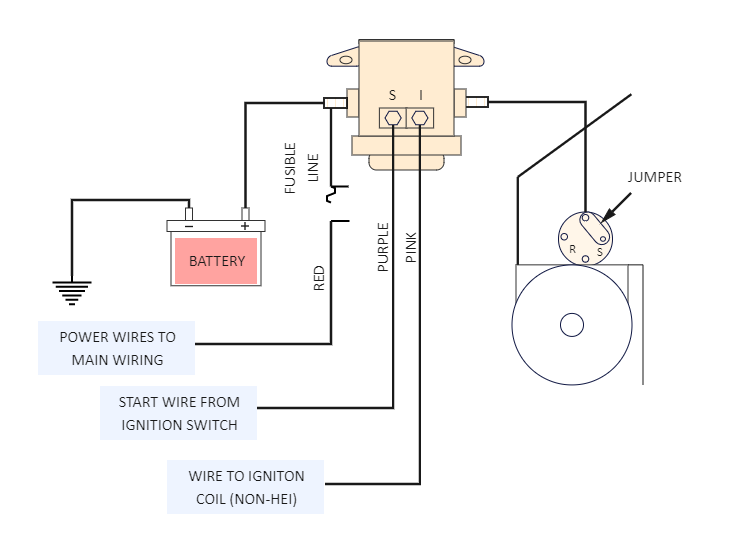

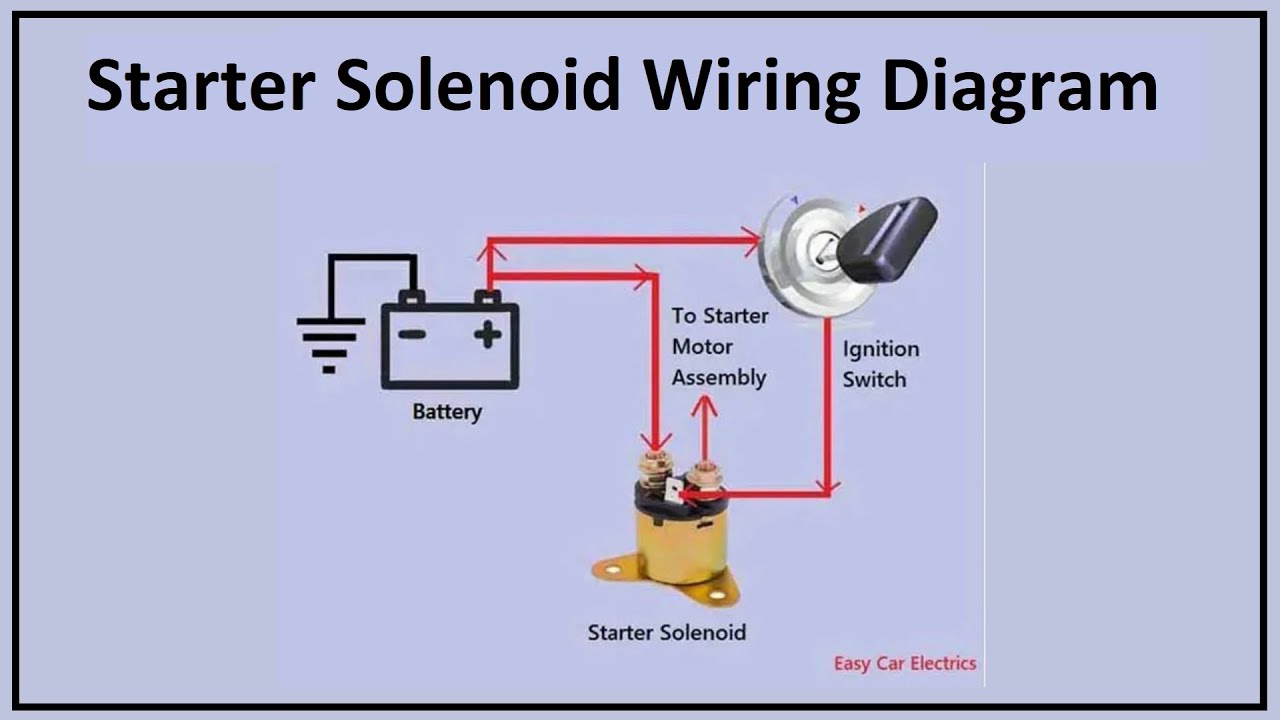

The wiring diagram for the 1970 Coronet starter solenoid provides a visual representation of the electrical flow through the starter circuit. Understanding this diagram is crucial for troubleshooting issues related to the starter system.The wiring diagram illustrates the connections between the battery, ignition switch, starter solenoid, starter motor, and other components.

It helps identify the path of electricity and pinpoint potential problems.

Starter Solenoid Circuit Flow

The starter solenoid circuit is responsible for supplying power to the starter motor when the ignition key is turned to the start position. The circuit begins at the battery, flows through the ignition switch, and then to the starter solenoid.

The solenoid acts as an electrically controlled switch, completing the circuit to the starter motor.The starter solenoid circuit consists of several key components:

- Battery:The battery provides the initial electrical energy for the entire circuit. It acts as the power source for the starter motor.

- Ignition Switch:The ignition switch controls the flow of electricity to the starter solenoid. When the key is turned to the start position, it completes the circuit, allowing current to flow to the solenoid.

- Starter Solenoid:The starter solenoid is an electromagnetic switch that acts as an intermediary between the battery and the starter motor. When the ignition switch is turned to the start position, the solenoid receives electrical current and activates a plunger. This plunger closes the main circuit, allowing high-current flow to the starter motor.

- Starter Motor:The starter motor is the device that rotates the engine crankshaft, starting the engine. It receives high-current flow from the solenoid when the circuit is closed.

- Wires:Wires connect all the components in the circuit, providing a path for the electrical current to flow.

Role of Each Wire in the Circuit

Each wire in the starter solenoid circuit plays a specific role:

- Battery Cable:The battery cable connects the positive terminal of the battery to the starter solenoid. This cable carries the main power supply to the solenoid.

- Ignition Switch Wire:The ignition switch wire connects the ignition switch to the starter solenoid. This wire carries the signal from the ignition switch to activate the solenoid.

- Starter Motor Cable:The starter motor cable connects the starter solenoid to the starter motor. This cable carries the high-current flow from the solenoid to the starter motor.

- Ground Wire:The ground wire connects the starter solenoid to the chassis of the vehicle. This wire provides a return path for the electrical current.

Comparison with Other Models

The wiring diagram for the 1970 Coronet starter solenoid is generally similar to those of other vehicles from the same era. However, there may be minor variations in the specific wire colors, connection points, and the number of wires used.For example, some models may have an additional wire for a starter relay, while others may have a different arrangement of the wires connected to the solenoid.

It is essential to consult the specific wiring diagram for the vehicle in question to ensure accurate identification and troubleshooting.

Troubleshooting Starter Solenoid Issues

The starter solenoid, a vital component in your 1970 Coronet’s starting system, can sometimes malfunction, leaving you stranded. This section delves into common starter solenoid problems, provides a step-by-step guide to troubleshooting a faulty solenoid, and explains the symptoms of a malfunctioning unit.

Common Starter Solenoid Problems

Starter solenoid problems can arise from various causes, including:

- Worn or damaged contacts:Over time, the contacts within the solenoid can wear down or become corroded, leading to poor electrical connection and preventing the starter motor from engaging.

- Stuck solenoid:The solenoid plunger can become stuck in the retracted position, preventing the starter motor from engaging. This can be caused by debris, corrosion, or a faulty solenoid spring.

- Faulty wiring:Damaged or corroded wiring connecting to the solenoid can interrupt the electrical flow, preventing the solenoid from functioning correctly.

- Overheated solenoid:Continuous use of the starter motor can overheat the solenoid, causing damage to its internal components. This can be caused by a faulty starter motor or a problem with the battery.

Troubleshooting a Faulty Starter Solenoid

Troubleshooting a faulty starter solenoid involves a series of steps to isolate the problem.

- Check the battery connections:Ensure the battery terminals are clean and securely connected. Loose or corroded connections can hinder electrical flow.

- Inspect the starter solenoid:Visually inspect the solenoid for any signs of damage, corrosion, or loose connections. If you find any issues, address them before proceeding.

- Test the solenoid with a multimeter:Use a multimeter to check the voltage at the solenoid terminals. With the key in the start position, you should measure battery voltage at the solenoid’s “S” terminal. If there’s no voltage, check the wiring leading to the solenoid.

- Check the solenoid plunger:With the key in the start position, tap on the solenoid plunger lightly. If the starter motor engages, the solenoid plunger might be stuck. This indicates a faulty solenoid.

- Check the starter motor:If the solenoid tests good but the starter motor still doesn’t engage, the issue may lie with the starter motor itself. You’ll need to test the starter motor separately to confirm.

Symptoms of a Faulty Starter Solenoid

Several symptoms can indicate a faulty starter solenoid:

- Clicking sound when starting:A clicking sound when you turn the key is a common symptom of a faulty starter solenoid. This indicates the solenoid is engaging but not providing enough power to turn the starter motor.

- No starter motor engagement:If the starter motor doesn’t engage at all, it could be due to a faulty starter solenoid. This is especially true if the solenoid clicks when you turn the key.

- Starter motor engages but doesn’t turn the engine:If the starter motor engages but doesn’t turn the engine, it could be a sign of a faulty starter solenoid. This is because the solenoid might not be providing enough power to turn the starter motor.

- Overheating:A starter solenoid that overheats can be a sign of a faulty unit. This can be caused by a variety of factors, such as worn contacts, a stuck solenoid plunger, or a faulty starter motor.

Replacing the Starter Solenoid

Replacing the starter solenoid on your 1970 Coronet is a relatively straightforward task that can be accomplished with basic tools and some mechanical aptitude. This procedure will guide you through the process, ensuring a smooth and successful replacement.

Tools and Materials

The tools and materials you’ll need for this replacement include:

- Socket wrench set (including 10mm, 13mm, and 17mm sockets)

- Ratchet wrench

- Extension bar

- Flathead screwdriver

- New starter solenoid

- Penetrating oil (optional)

- Safety glasses

- Gloves

Before you begin, ensure you have a new starter solenoid that’s compatible with your 1970 Coronet. Refer to your owner’s manual or consult with a trusted auto parts supplier for the correct part number.

Safety Precautions

Safety is paramount during any automotive repair. Follow these precautions to ensure a safe and successful replacement:

- Disconnect the negative battery terminal before starting any work on the electrical system. This prevents accidental electrical shock and short circuits.

- Wear safety glasses to protect your eyes from flying debris.

- Use gloves to protect your hands from grease and grime.

- Work in a well-ventilated area to avoid inhaling fumes from battery acid or other chemicals.

- Be cautious when handling the battery terminals, as they can carry a significant electrical charge even when disconnected.

Procedure for Replacing the Starter Solenoid

- Locate the Starter Solenoid:The starter solenoid is typically located near the starter motor, usually on the passenger side of the engine compartment. It’s a cylindrical device with electrical terminals and a small metal rod protruding from one end.

- Disconnect the Battery Terminal:Disconnect the negative battery terminal using a wrench. This prevents accidental electrical shock and short circuits during the replacement process.

- Remove the Old Starter Solenoid:

- Identify the wires connected to the solenoid. Note their positions, as you’ll need to reconnect them to the new solenoid in the same configuration.

- Use a socket wrench to loosen the mounting bolts holding the solenoid to the starter motor.

- Once the bolts are loose, gently pull the solenoid away from the starter motor, taking care not to damage any wires or the starter motor itself.

- Install the New Starter Solenoid:

- Align the new solenoid with the mounting holes on the starter motor.

- Reconnect the wires to the new solenoid, ensuring they are connected to the correct terminals.

- Tighten the mounting bolts securely.

- Reconnect the Battery Terminal:Reconnect the negative battery terminal. Ensure the connection is secure and tight.

- Test the Starter:Turn the ignition key to the “start” position. The starter should engage, and the engine should crank over. If the starter does not engage, double-check your connections and ensure the battery is charged.

Starter Solenoid Function and Operation

The starter solenoid is a critical component in the starting system of your 1970 Coronet, acting as the intermediary between the ignition switch and the starter motor. It’s a powerful electromagnet that engages the starter motor, allowing it to crank the engine and initiate combustion.

Yo, tryna fix that 70 Coronet starter solenoid? Wiring diagrams are your best friend, man. Check out this jd 111 1983 wiring diagram for a similar setup. Once you get the hang of it, you’ll be a wiring wiz in no time, fixing that Coronet and hitting the streets.

The Operation of the Starter Solenoid

The starter solenoid’s operation is straightforward. When you turn the ignition key to the “Start” position, a small electrical current flows through the solenoid’s coil. This current creates a magnetic field, which pulls a plunger or armature towards the solenoid’s core.

This action completes a heavier electrical circuit, allowing a much larger current to flow from the battery to the starter motor.

Engaging the Starter Motor

When the plunger is pulled towards the core, it also engages a mechanical linkage. This linkage, typically a lever or rod, physically connects the solenoid to the starter motor’s drive pinion. This engagement allows the pinion to mesh with the engine’s flywheel, enabling the starter motor to rotate the crankshaft and initiate the combustion process.

Role in the Starting Process

The starter solenoid plays a crucial role in the starting process, acting as a relay that bridges the gap between the low-current ignition switch and the high-current starter motor. This relay function is essential because the ignition switch is not designed to handle the high current required by the starter motor.

The starter solenoid effectively “switches” the high current from the battery to the starter motor when the ignition key is turned to the “Start” position, allowing the engine to crank and start.

Starter Solenoid Testing

Testing a starter solenoid is crucial for diagnosing and resolving starting problems in your 1970 Coronet. By performing these tests, you can identify if the solenoid itself is faulty or if the issue lies elsewhere in the starting system.

Testing the Starter Solenoid

Before you begin testing, gather the necessary tools and equipment:

- Test light or multimeter

- Screwdriver

- Wire jumper

To test the starter solenoid, follow these steps:

- Disconnect the battery negative terminal.This is a safety precaution to prevent electrical shocks.

- Locate the starter solenoid.It is typically mounted on the firewall near the starter motor. Refer to your vehicle’s wiring diagram for the exact location.

- Identify the solenoid terminals.The solenoid has two large terminals (S and R) and two smaller terminals (I and BAT).

- Test the small terminal (I) to ground.Connect the positive lead of your test light or multimeter to the small terminal (I) and the negative lead to a good ground point on the vehicle’s frame. Turn the ignition key to the “start” position. The test light should illuminate or the multimeter should show a voltage reading if the ignition switch is supplying power to the solenoid.

- Test the large terminal (S) to ground.Connect the positive lead of your test light or multimeter to the large terminal (S) and the negative lead to a good ground point on the vehicle’s frame. Turn the ignition key to the “start” position. The test light should illuminate or the multimeter should show a voltage reading if the solenoid is receiving power from the ignition switch.

- Test the large terminal (R) to ground.Connect the positive lead of your test light or multimeter to the large terminal (R) and the negative lead to a good ground point on the vehicle’s frame. Turn the ignition key to the “start” position. The test light should illuminate or the multimeter should show a voltage reading if the solenoid is receiving power from the battery.

- Test the small terminal (BAT) to ground.Connect the positive lead of your test light or multimeter to the small terminal (BAT) and the negative lead to a good ground point on the vehicle’s frame. Turn the ignition key to the “start” position. The test light should illuminate or the multimeter should show a voltage reading if the battery is supplying power to the solenoid.

- Check for continuity between the large terminals (S and R).Connect the positive lead of your multimeter to the large terminal (S) and the negative lead to the large terminal (R). The multimeter should show continuity if the solenoid is working properly.

- If any of the tests fail, the starter solenoid is likely defective.You will need to replace the solenoid to restore proper starting functionality.

Starter Solenoid Maintenance

The starter solenoid is a crucial component in your 1970 Coronet’s starting system, responsible for relaying electrical current to the starter motor. Neglecting its maintenance can lead to starting problems, potentially stranding you on the road. Implementing a routine maintenance schedule helps ensure optimal performance and extends the life of your starter solenoid.

Importance of Starter Solenoid Maintenance

Regular maintenance is essential for the proper functioning of your starter solenoid. This includes visual inspection, cleaning, and testing to identify potential issues before they escalate into major problems. Early detection and resolution of minor issues can prevent costly repairs and ensure a reliable starting system.

Routine Maintenance Tasks

A consistent maintenance routine helps identify and address potential problems before they escalate. This includes:

- Visual Inspection:Regularly inspect the starter solenoid for any signs of damage, corrosion, or loose connections. Look for cracks, burns, or any physical damage that might compromise its functionality.

- Cleaning:Use a wire brush or compressed air to clean any accumulated dirt, grime, or corrosion from the solenoid’s terminals and connections. This ensures a clean and secure electrical connection.

- Tightening Connections:Periodically check and tighten all the terminal connections on the solenoid. Loose connections can cause resistance and hinder the flow of electricity to the starter motor.

- Testing:Use a multimeter to test the solenoid’s continuity and resistance. This verifies the solenoid’s ability to conduct electricity and identify any potential issues with its internal components.

Preventing Starter Solenoid Issues

Following these preventive measures can significantly reduce the risk of starter solenoid problems:

- Battery Maintenance:A healthy battery is crucial for the starter solenoid’s operation. Ensure your battery is properly charged and its terminals are clean and tight. A weak battery can strain the solenoid, leading to premature failure.

- Proper Wiring:Ensure all wiring connected to the solenoid is in good condition and properly secured. Loose or corroded wires can create resistance, hindering the flow of electricity and potentially damaging the solenoid.

- Avoid Overheating:Excessive heat can damage the solenoid’s internal components. Avoid prolonged cranking or multiple attempts to start the engine, as this can overheat the solenoid.

- Regular Inspections:Performing routine visual inspections and cleaning can help identify potential issues early on. This allows for timely repairs, preventing major problems from developing.

Starter Solenoid History

The starter solenoid, a crucial component in the automotive starting system, has a rich history that parallels the evolution of the internal combustion engine itself. Its development has been driven by the need for a reliable and efficient method to initiate the engine’s combustion cycle.The starter solenoid’s journey began with the emergence of the electric starter motor in the early 20th century.

Early starter systems relied on a direct connection between the battery and the starter motor, often resulting in excessive current draw and potential damage to the battery or wiring.

Early Development and Evolution

The introduction of the starter solenoid as a relay in the early 1900s revolutionized the starting process. Its primary function was to isolate the high-current path between the battery and the starter motor, preventing excessive current flow and protecting the electrical system.

- Early Solenoids:These solenoids were often large and bulky, requiring significant space within the engine compartment. They typically employed a mechanical linkage system to engage the starter motor, which could be prone to wear and tear.

- Electromagnetic Solenoids:The development of electromagnetic solenoids in the mid-20th century brought about significant improvements in size, efficiency, and reliability. These solenoids utilized an electromagnetic coil to engage a plunger, which in turn connected the starter motor to the battery.

- Modern Solenoids:Today’s starter solenoids are compact, durable, and integrated with the starter motor for greater efficiency and convenience. They typically incorporate a built-in thermal protection system to prevent overheating and potential damage.

Interesting Facts

- The starter solenoid is often referred to as the “starter relay” or “starter switch” due to its function as a relay that connects the battery to the starter motor.

- The starter solenoid’s operating principle is based on the electromagnetic force generated by an electric current flowing through a coil. This force attracts a plunger, which completes the electrical circuit and engages the starter motor.

- The starter solenoid is a critical component in the starting system, and its failure can prevent the engine from starting.

Starter Solenoid Applications

Starter solenoids are essential components in the ignition system of most vehicles, playing a crucial role in initiating the engine’s combustion cycle. They are found in various types of vehicles, including cars, trucks, motorcycles, boats, and even industrial equipment. Starter solenoids are designed to bridge the electrical circuit between the battery and the starter motor, allowing the high current required to crank the engine to flow.

They work by using an electromagnet to engage a set of contacts, completing the circuit and powering the starter motor.

Starter Solenoid Applications in Different Vehicle Types

Starter solenoids are used in a wide range of vehicles, each with its own unique requirements. Here are some examples:

- Cars:In gasoline-powered cars, the starter solenoid is typically mounted on the starter motor itself. It receives a signal from the ignition switch, which activates the solenoid, allowing the starter motor to engage the engine.

- Trucks:Heavy-duty trucks often have more robust starter solenoids due to the higher power demands of their engines. These solenoids may be located on the starter motor or on a separate mounting bracket.

- Motorcycles:Motorcycles use smaller, compact starter solenoids that are designed to fit within the limited space available on the motorcycle’s frame.

- Boats:Marine starter solenoids are often waterproof and corrosion-resistant to withstand the harsh environment of a boat’s engine compartment.

- Industrial Equipment:Heavy-duty industrial equipment, such as forklifts and construction machinery, requires starter solenoids that can handle the high current demands of their large engines.

Starter Solenoid Operation in Different Engine Types

Starter solenoids work similarly across various engine types, but there are some variations in their operation depending on the engine’s design.

- Gasoline Engines:In gasoline engines, the starter solenoid engages the starter motor, which rotates the crankshaft, ultimately turning the pistons and igniting the fuel-air mixture.

- Diesel Engines:Diesel engines have higher compression ratios than gasoline engines, requiring more power to turn the crankshaft. Starter solenoids in diesel engines are often designed to handle higher current loads to accommodate this requirement.

- Electric Vehicles:Electric vehicles do not use starter solenoids in the traditional sense. They rely on electronic controllers that manage the flow of electricity from the battery to the electric motor, which drives the wheels.

Examples of Different Starter Solenoid Models

There are numerous models of starter solenoids available on the market, each designed for specific applications. Some popular examples include:

- Bosch Starter Solenoids:Bosch is a leading manufacturer of automotive components, including starter solenoids. Their solenoids are known for their reliability and durability.

- Delphi Starter Solenoids:Delphi is another major supplier of starter solenoids, offering a wide range of models for various vehicle applications.

- ACDelco Starter Solenoids:ACDelco is a popular brand of automotive parts, including starter solenoids. Their solenoids are known for their affordability and compatibility with a wide range of vehicles.

Starter Solenoid Technology

The starter solenoid, a vital component in automotive systems, has undergone significant advancements in recent years. These advancements have resulted in more efficient, reliable, and durable starter solenoids, contributing to a smoother and more reliable starting experience.

Modern Starter Solenoid Features and Benefits

Modern starter solenoids incorporate various technological advancements that enhance their performance and longevity. These features include:

- Improved Contact Materials:Modern solenoids often utilize high-quality contact materials like silver-cadmium oxide or silver-nickel alloys. These materials offer superior conductivity, reducing resistance and heat buildup, leading to longer life and improved performance.

- Enhanced Insulation:Modern starter solenoids feature advanced insulation materials that withstand higher temperatures and resist moisture, preventing short circuits and ensuring long-term reliability.

- Sealed Construction:Many modern solenoids are sealed units, protecting internal components from dust, moisture, and other contaminants. This design improves durability and extends the solenoid’s lifespan.

- Compact Design:Advancements in solenoid design have led to more compact and efficient units, saving space in the engine compartment and facilitating easier installation.

- Higher Current Capacity:Modern starter solenoids are designed to handle higher current loads, enabling them to power larger and more powerful starter motors efficiently.

Comparison of Traditional and Modern Starter Solenoids

Traditional starter solenoids often relied on simpler designs and materials, making them prone to wear and tear, especially in harsh environments. Modern starter solenoids offer significant advantages over their predecessors:

| Feature | Traditional Starter Solenoid | Modern Starter Solenoid |

|---|---|---|

| Contact Materials | Brass or copper | Silver-cadmium oxide or silver-nickel alloys |

| Insulation | Basic insulation materials | Advanced insulation materials (heat-resistant, moisture-resistant) |

| Construction | Open design, susceptible to contamination | Sealed construction, protected from contaminants |

| Current Capacity | Limited current handling capability | Higher current capacity, enabling efficient operation of larger starter motors |

| Lifespan | Shorter lifespan due to wear and tear | Longer lifespan due to improved materials and design |

Modern starter solenoids are a testament to the continuous advancements in automotive technology. They offer a significant improvement in performance, reliability, and durability compared to their traditional counterparts.

User Queries

What are the symptoms of a faulty starter solenoid?

A faulty starter solenoid can manifest in various ways, including a clicking sound when attempting to start the engine, a slow cranking speed, or no response at all.

How often should I replace the starter solenoid?

While there’s no set replacement schedule, it’s advisable to inspect and test the starter solenoid regularly, especially if you notice any starting issues. If the solenoid is exhibiting signs of wear or damage, it’s best to replace it promptly.

Can I test the starter solenoid without removing it?

Yes, you can perform a basic test using a multimeter to check for continuity and voltage across the solenoid’s terminals. However, for a more thorough assessment, it’s recommended to remove the solenoid for a more comprehensive test.

What are some common causes of starter solenoid problems?

Common causes include corrosion on the terminals, a faulty solenoid switch, worn-out internal components, or a damaged wiring harness.