The 4L60E valve body diagram is a blueprint into the heart of a transmission, a complex system that orchestrates the smooth flow of power from engine to wheels. It’s a map of intricate pathways, where fluid pressure dances and solenoids sing, orchestrating the symphony of gear changes that keep your vehicle moving.

Understanding this diagram unlocks the secrets of the 4L60E, revealing the delicate balance of forces that govern its performance and longevity.

Imagine the 4L60E as a conductor, meticulously directing the flow of fluid through a network of intricate passages. The valve body, the conductor’s baton, controls the fluid pressure and directs its flow to achieve the desired gear ratios. This intricate interplay of fluid pressure and valve body components allows the transmission to seamlessly shift between gears, adapting to different driving conditions with remarkable precision.

Introduction to the 4L60E Transmission

The 4L60E transmission, also known as the “4L60” or “4L65E,” is a widely recognized automatic transmission designed by General Motors (GM) for rear-wheel-drive (RWD) and all-wheel-drive (AWD) vehicles. It is a robust and versatile transmission, known for its durability and reliability, making it a popular choice for a wide range of automotive applications.

The 4L60E plays a crucial role in the powertrain system, allowing for smooth and efficient power delivery to the wheels.

Purpose and Function of the 4L60E Transmission

The primary purpose of the 4L60E transmission is to manage the flow of power from the engine to the wheels, allowing for smooth acceleration, efficient cruising, and effective load-carrying capabilities. The transmission accomplishes this by providing multiple gear ratios, allowing the engine to operate at its optimal speed for different driving conditions.

The 4L60E is a four-speed automatic transmission, meaning it has four distinct gear ratios that can be selected electronically by the transmission control module (TCM). The TCM monitors various engine and vehicle parameters, such as engine speed, throttle position, and vehicle speed, to determine the optimal gear ratio for the current driving conditions.

Applications of the 4L60E Transmission

The 4L60E transmission has found widespread use in a diverse range of GM vehicles, including:

- Chevrolet: Silverado, Tahoe, Suburban, Corvette, Camaro, Impala, and Monte Carlo

- GMC: Sierra, Yukon, and Envoy

- Buick: LeSabre, Regal, and Park Avenue

- Cadillac: DeVille, Seville, and Eldorado

- Oldsmobile: Aurora, Bravada, and Intrigue

- Pontiac: Grand Prix, Bonneville, and Firebird

The transmission’s versatility and compatibility with various engine sizes and configurations have contributed to its widespread adoption across multiple vehicle models.

Development and Evolution of the 4L60E Transmission

The 4L60E transmission has a rich history, with its development and evolution spanning several decades. The 4L60E’s roots can be traced back to the 1980s with the introduction of the THM700R4 transmission, a three-speed automatic transmission. The THM700R4 was later upgraded to a four-speed transmission, known as the 4L60, which served as the foundation for the 4L60E.

The “E” in 4L60E stands for “electronic,” signifying the introduction of electronic control, which enhanced the transmission’s performance, efficiency, and reliability.

Anatomy of the 4L60E Valve Body

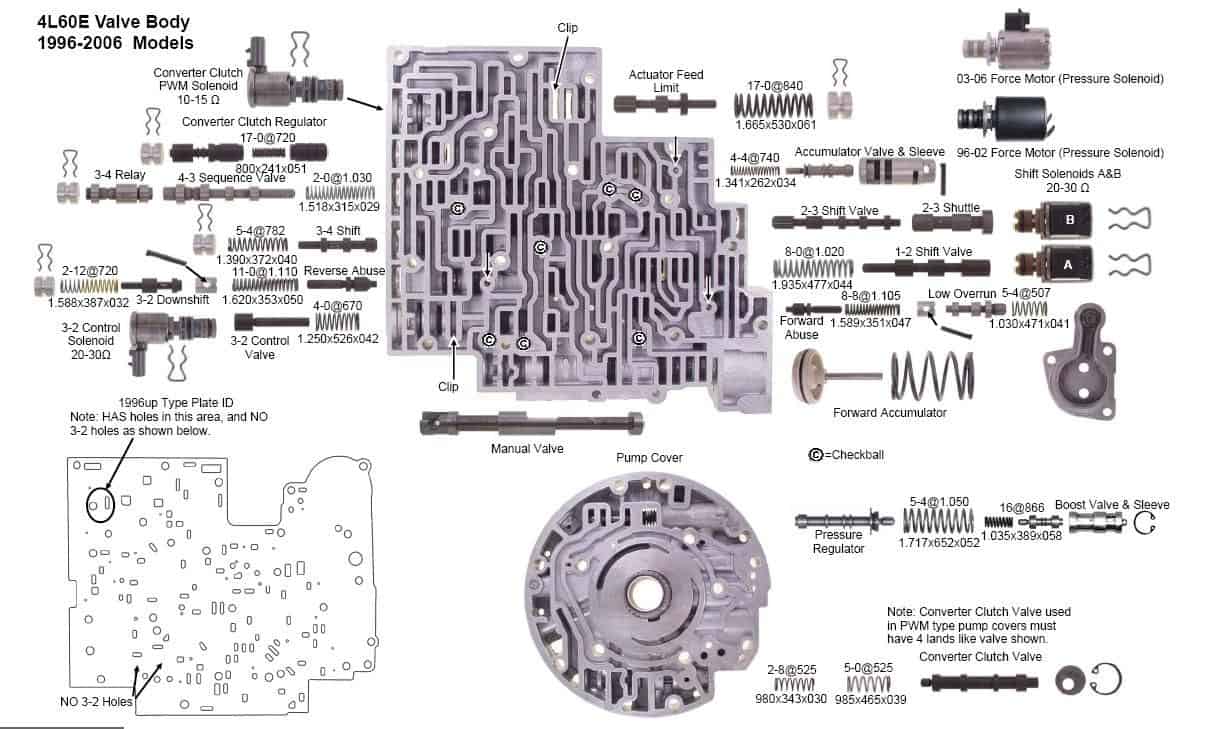

The valve body of the 4L60E transmission is a complex assembly that controls the flow of hydraulic fluid throughout the transmission. It is responsible for shifting gears, regulating pressure, and controlling clutch engagement. This intricate system is composed of various components, each with a specific function, ensuring smooth and efficient transmission operation.

Understanding the 4l60e valve body diagram is crucial for diagnosing and repairing transmission issues. It’s a complex system with numerous valves and passages, each playing a vital role in gear selection and fluid flow. If you’re working on a 13wq91ap009 part, you might find the 13wq91ap009 parts diagram helpful for identifying specific components.

This knowledge can then be applied to understanding the corresponding parts within the 4l60e valve body diagram, aiding in troubleshooting and repair efforts.

Internal Components and Function

The 4L60E valve body houses numerous components that work together to manage the transmission’s hydraulic system. The key components include solenoids, check balls, and passages, which are interconnected to control the fluid flow. The solenoids are electrically controlled valves that open and close hydraulic passages, allowing fluid to flow to specific areas of the transmission.

The check balls are small, spherical components that allow fluid to flow in one direction only, preventing backflow. The passages are channels within the valve body that direct the flow of hydraulic fluid.

Valve Body Structure and Layout

The valve body is constructed from a series of plates and internal components, including the accumulator and pressure regulator. The accumulator is a reservoir that stores hydraulic fluid under pressure, providing a buffer to help with quick shifting. The pressure regulator controls the pressure of the hydraulic fluid within the transmission, ensuring proper operation of the clutches and brakes.

The valve body also houses a number of filters and screens to prevent debris from entering the transmission’s hydraulic system.

Components, Functions, and Failure Modes

| Component | Function | Typical Failure Modes |

|---|---|---|

| Solenoids | Control fluid flow to specific areas of the transmission | Sticking, electrical failure, worn seals |

| Check Balls | Prevent backflow of hydraulic fluid | Worn or damaged, stuck in the passage |

| Passages | Direct the flow of hydraulic fluid | Blockage due to debris, corrosion, or wear |

| Accumulator | Stores hydraulic fluid under pressure, assists with quick shifting | Leakage, internal failure, improper charging |

| Pressure Regulator | Controls the pressure of the hydraulic fluid | Sticking, wear, internal failure |

Function of the Valve Body: 4l60e Valve Body Diagram

The valve body is the brain of the 4L60E transmission, responsible for directing the flow of hydraulic fluid to the clutches and brakes, ultimately controlling the gear selection and operation of the transmission. It’s a complex network of valves, passages, and control solenoids that work together to manage the fluid pressure and direct it to the appropriate components.

Control of Fluid Flow and Gear Ratios

The valve body regulates the flow of hydraulic fluid to different components of the transmission, enabling the selection of different gear ratios. The valve body contains a series of valves and passages that can be opened or closed by the transmission control module (TCM) based on various inputs, including engine speed, vehicle speed, throttle position, and transmission temperature.

- Directional Control Valves:These valves direct the flow of fluid to specific clutches and brakes within the transmission. For example, the 1-2 clutch applies the first and second gear clutches, while the 3-4 clutch applies the third and fourth gear clutches. By controlling the fluid flow to these clutches, the valve body can engage and disengage specific gear sets to achieve the desired gear ratio.

- Pressure Regulating Valves:The valve body also regulates the pressure of the hydraulic fluid. These valves control the amount of fluid pressure applied to the clutches and brakes, ensuring smooth shifting and optimal performance.

- Solenoids:Solenoids are electro-magnetic valves that are controlled by the TCM. When the TCM sends an electrical signal to a solenoid, it opens or closes a valve, allowing or blocking the flow of fluid to specific components. Solenoids play a critical role in managing fluid pressure, shifting gears, and applying brakes.

Regulation of Pressure and Shifting

The valve body is responsible for managing the pressure of the hydraulic fluid within the transmission, ensuring smooth shifting and optimal performance. The pressure applied to the clutches and brakes directly influences the gear selection and the overall transmission operation.

- Pressure Control:The valve body uses pressure regulating valves to maintain a specific pressure within the transmission system. This pressure is crucial for the proper engagement and disengagement of the clutches and brakes, as well as for ensuring smooth and efficient gear changes.

- Shifting:The valve body directs the flow of fluid to the clutches and brakes to engage and disengage specific gear sets, allowing the transmission to shift between gears. The TCM sends signals to the valve body’s solenoids, which open or close valves, controlling the flow of fluid and ultimately the shifting process.

- Shift Quality:The valve body plays a critical role in shift quality. By precisely regulating the fluid pressure and flow, the valve body ensures smooth and seamless gear changes. Incorrect fluid pressure or improper valve operation can lead to harsh or delayed shifting, impacting the driving experience.

Interaction with the TCM

The valve body works in conjunction with the transmission control module (TCM) to manage gear selection and transmission operation. The TCM receives various inputs from sensors throughout the vehicle, including engine speed, vehicle speed, throttle position, and transmission temperature. Based on these inputs, the TCM calculates the optimal gear selection and sends electrical signals to the valve body’s solenoids to control the flow of hydraulic fluid.

- Gear Selection:The TCM determines the appropriate gear ratio based on driving conditions and sends signals to the valve body to engage or disengage specific clutches and brakes.

- Shift Timing:The TCM controls the timing of gear changes, ensuring smooth transitions between gears and preventing harsh shifting.

- Shift Strategy:The TCM implements various shift strategies, such as “kickdown” or “power upshift,” to provide optimal performance and fuel efficiency.

Common Valve Body Issues and Symptoms

The 4L60E valve body is a complex component that plays a crucial role in the proper functioning of the transmission. Over time, various issues can arise within the valve body, leading to a range of symptoms that can indicate potential problems.

Understanding these common issues and their associated symptoms can help diagnose and address valve body problems effectively.

Solenoid Failure

Solenoids are electro-mechanical valves that control the flow of hydraulic fluid within the transmission. They are responsible for engaging and disengaging clutches and bands, which ultimately control gear selection and shifting. When a solenoid fails, it can prevent the transmission from shifting correctly, resulting in a variety of symptoms.

- Slipping Gears:A failed solenoid may not properly engage or disengage clutches, causing the transmission to slip between gears. This is often accompanied by a noticeable “slipping” sensation during acceleration.

- Rough Shifting:Solenoid failure can lead to harsh or delayed shifts, as the transmission struggles to select the appropriate gear. This can manifest as a sudden jerk or bang when shifting, especially under heavy acceleration or deceleration.

- Transmission Failure:In severe cases, a failed solenoid can completely disable the transmission, leaving the vehicle unable to move. This occurs when the solenoid malfunctions to the point where it can no longer control the hydraulic fluid flow necessary for proper operation.

Troubleshooting solenoid failure involves checking for continuity and resistance within the solenoid circuit using a multimeter. If a solenoid is found to be faulty, it must be replaced with a new one.

Worn Check Balls, 4l60e valve body diagram

Check balls are small, spherical components that act as one-way valves within the valve body. They are designed to prevent backflow of hydraulic fluid, ensuring that the transmission operates correctly. Over time, check balls can wear out or become lodged in the valve body passages, hindering fluid flow and causing transmission issues.

- Rough Shifting:Worn check balls can lead to erratic fluid flow, resulting in rough or delayed shifts. The transmission may struggle to engage or disengage gears smoothly, causing a noticeable clunk or shudder during shifting.

- Erratic Gear Selection:Worn check balls can also interfere with the proper selection of gears, causing the transmission to randomly shift between gears or fail to engage certain gears altogether. This can lead to unpredictable driving behavior and potentially unsafe situations.

- Fluid Leaks:In some cases, worn check balls can allow fluid to leak past their seals, leading to transmission fluid loss. This can cause a noticeable decrease in transmission fluid level and potentially damage the transmission if not addressed promptly.

Diagnosing worn check balls typically involves inspecting the valve body for any signs of damage or wear. Replacing worn check balls is usually a straightforward process that can be done by a qualified mechanic.

Clogged Passages

The valve body contains numerous passages that allow hydraulic fluid to flow between different components. Over time, these passages can become clogged with debris, such as metal shavings, dirt, or varnish. Clogged passages restrict fluid flow, hindering the transmission’s ability to function properly.

- Shifting Problems:Clogged passages can lead to a variety of shifting issues, including slipping, rough shifting, and delayed engagement. The transmission may struggle to select the appropriate gear or experience erratic shifting behavior.

- Fluid Pressure Issues:Clogged passages can also affect hydraulic fluid pressure, leading to problems with clutch engagement and band application. This can result in slipping, poor acceleration, and potentially transmission failure.

- Overheating:Restricted fluid flow due to clogged passages can cause the transmission to overheat. This can lead to damage to internal components and potentially catastrophic failure.

To diagnose clogged passages, a thorough inspection of the valve body is required. A qualified mechanic can use specialized tools to flush and clean the passages, restoring proper fluid flow.

Valve Body Diagram Interpretation

A valve body diagram is an essential tool for understanding the internal workings of the 4L60E transmission. It provides a visual representation of the intricate network of passages, valves, and solenoids that control the flow of transmission fluid, ultimately dictating gear selection and clutch engagement.

Understanding the Components

The valve body diagram is a complex map that shows the layout of various components, including the pressure regulator, accumulator, and solenoids. Each component plays a crucial role in controlling the transmission fluid flow, and understanding their functions is key to interpreting the diagram.

- Pressure Regulator: This valve maintains a constant line pressure within the transmission, ensuring proper clutch engagement and gear changes. It regulates the flow of fluid to the various clutch packs, ensuring optimal performance.

- Accumulator: This component acts as a temporary storage reservoir for transmission fluid, providing a cushion to absorb pressure surges and prevent damage to the valve body.

- Solenoids: These electrically controlled valves are responsible for directing the flow of transmission fluid to specific clutch packs, enabling gear changes and clutch engagement. The diagram shows the location and function of each solenoid, providing insights into how they influence the transmission’s operation.

Transmission Fluid Flow Paths

The valve body diagram is a visual guide to the fluid flow paths through the transmission. Understanding these paths is crucial for diagnosing and troubleshooting issues related to fluid pressure and clutch engagement.

| Operating Condition | Fluid Flow Path | Valve Body Components | Description |

|---|---|---|---|

| Park/Neutral | Fluid circulates through the valve body, bypassing the clutches | Pressure regulator, accumulator, solenoids | No power is transmitted to the wheels. |

| First Gear | Fluid flows to the first gear clutch pack | Pressure regulator, accumulator, first gear solenoid | The first gear clutch engages, providing torque to the wheels. |

| Second Gear | Fluid flows to the second gear clutch pack | Pressure regulator, accumulator, second gear solenoid | The second gear clutch engages, providing a higher gear ratio. |

| Third Gear | Fluid flows to the third gear clutch pack | Pressure regulator, accumulator, third gear solenoid | The third gear clutch engages, providing a higher gear ratio. |

| Fourth Gear | Fluid flows to the fourth gear clutch pack | Pressure regulator, accumulator, fourth gear solenoid | The fourth gear clutch engages, providing the highest gear ratio. |

Significance of Understanding the Diagram

Understanding the valve body diagram is essential for anyone working on a 4L60E transmission, whether it’s for troubleshooting, repair, or performance upgrades.

- Troubleshooting: By tracing the fluid flow paths and identifying the components involved, technicians can pinpoint the source of transmission problems, such as slipping, rough shifting, or lack of power.

- Repair: The diagram helps technicians locate and identify faulty components, enabling them to perform accurate repairs and ensure proper functionality.

- Performance Upgrades: Understanding the fluid flow paths and valve body components allows for the implementation of performance upgrades, such as installing high-flow solenoids or modifying the valve body for increased pressure and improved shifting performance.

Commonly Asked Questions

What is the purpose of the accumulator in the 4L60E valve body?

The accumulator acts as a pressure reservoir, absorbing pressure spikes and providing a smooth, controlled application of clutch pressure during gear changes.

What are the most common symptoms of a failing 4L60E valve body?

Common symptoms include slipping gears, rough shifting, delayed engagement, and transmission failure.

How often should the 4L60E valve body be serviced?

While there’s no specific mileage interval, it’s recommended to inspect and service the valve body at least every 100,000 miles or when experiencing transmission problems.

Can I replace individual components in the valve body, or do I need to replace the entire unit?

Many components like solenoids and check balls can be replaced individually, but in some cases, the entire valve body may need to be replaced, depending on the extent of damage.

What are the benefits of upgrading the 4L60E valve body?

Upgrades can improve shift performance, increase durability, and enhance overall transmission reliability.