4.5 hp mercury outboard throttle linkage diagram pdf is your key to unlocking the secrets of your Mercury outboard engine. This comprehensive guide walks you through the intricacies of the throttle linkage system, empowering you to understand its components, troubleshoot potential issues, and maintain peak performance.

Whether you’re a seasoned boater or a novice enthusiast, this diagram is your essential companion for a smooth and enjoyable boating experience.

Imagine cruising effortlessly across the water, the engine purring with precision, thanks to your newfound knowledge of the throttle linkage. This diagram isn’t just a collection of lines and symbols; it’s a roadmap to understanding the heart of your Mercury outboard, empowering you to navigate the world of boating with confidence.

Components of the Throttle Linkage System

The throttle linkage system is a critical component of an outboard motor, responsible for transmitting the operator’s throttle input to the engine, ultimately controlling the speed and power of the motor. This intricate system comprises several interconnected components, each playing a vital role in ensuring smooth and precise throttle control.

Throttle Control Lever

The throttle control lever, typically located on the steering console or tiller handle, serves as the primary interface between the operator and the engine. When the operator moves the lever, it initiates a chain of events that ultimately adjust the engine’s speed.

The lever’s movement is translated into mechanical motion through a series of interconnected components, ultimately reaching the carburetor or fuel injection system to regulate fuel flow and, consequently, engine speed.

Throttle Cable

The throttle cable is a flexible, steel-braided cable that connects the throttle control lever to the throttle arm on the engine. It transmits the mechanical movement of the throttle control lever to the throttle arm, allowing the operator’s input to be transferred to the engine.

The throttle cable is designed to be durable and flexible, enabling smooth and reliable operation in various marine environments.

Throttle Arm

The throttle arm is a lever attached to the engine’s carburetor or fuel injection system. It receives the mechanical input from the throttle cable and translates this motion into the adjustment of the carburetor’s throttle valve or the fuel injection system’s fuel flow rate.

This direct connection between the throttle arm and the fuel delivery system ensures precise control over engine speed.

Throttle Linkage Components

The throttle linkage system often includes additional components, depending on the specific engine model and design. These components can include:

- Throttle return spring:This spring is responsible for returning the throttle arm to its idle position when the throttle control lever is released. It ensures that the engine returns to idle speed after the operator releases the throttle.

- Throttle linkage rods:These rods connect the throttle arm to other components, such as the carburetor or fuel injection system, and transmit the mechanical movement of the throttle arm to these components. They are typically made of durable metal to withstand the forces involved in throttle operation.

- Throttle linkage pins and bushings:These components provide smooth and precise movement within the throttle linkage system. They reduce friction and wear, ensuring that the throttle linkage operates smoothly and efficiently.

Interplay of Components

The throttle linkage system functions as a cohesive unit, with each component working in harmony to translate the operator’s throttle input into precise control of the engine’s speed. The throttle control lever initiates the process, transmitting the operator’s input to the throttle cable.

The throttle cable then conveys this input to the throttle arm, which in turn adjusts the carburetor or fuel injection system to regulate fuel flow and engine speed. The throttle return spring ensures that the throttle arm returns to its idle position when the throttle control lever is released, while the throttle linkage rods and pins/bushings provide smooth and efficient operation.

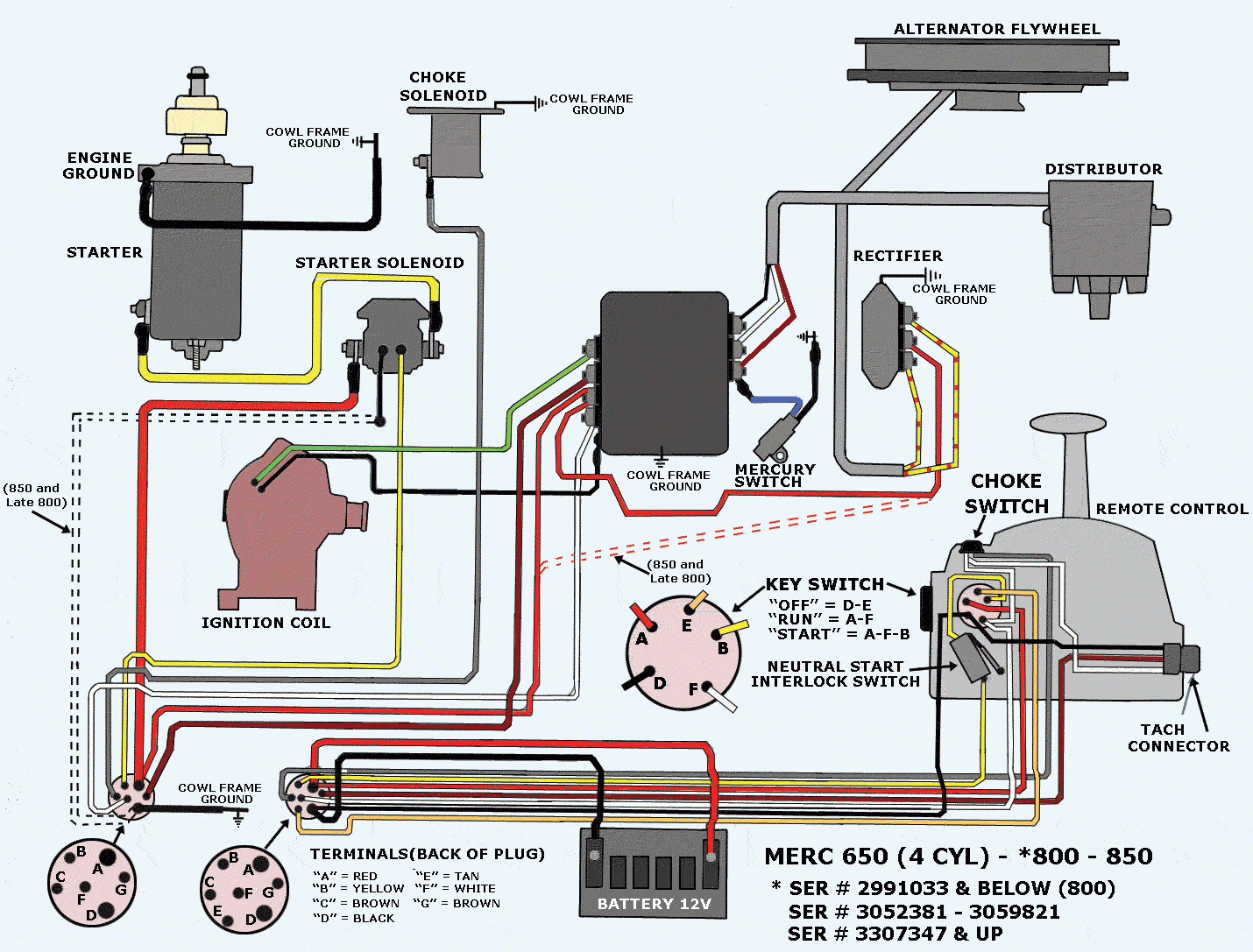

Understanding the Throttle Linkage Diagram

The throttle linkage diagram is a visual representation of the components and their connections within the throttle system of a 4.5 hp Mercury outboard motor. It serves as a guide for understanding the mechanism of throttle control and troubleshooting any issues related to the system.

Diagram Layout and Organization

The diagram typically presents a simplified representation of the throttle linkage system, with each component depicted in a schematic form. The layout of the diagram is designed for clarity and ease of understanding.

- Components are generally arranged in a logical order, following the flow of movement from the throttle lever to the carburetor.

- Arrows are used to indicate the direction of motion for each component.

- The diagram often includes labels or annotations to identify each component and its function.

Symbols and Notations

The throttle linkage diagram uses specific symbols and notations to represent different components and their interactions.

Lines

Solid lines represent rigid connections, while dashed lines indicate flexible connections.

Arrows

Arrows indicate the direction of movement for each component.

Circles

Circles may represent pivot points or connection points.

Squares

Squares may represent fixed points or attachment points.

Labels

Labels are used to identify each component and its function.

Interpreting the Throttle Linkage Diagram

Interpreting the throttle linkage diagram involves understanding the relationship between the components and how they work together to control the throttle.

Identify the throttle lever

This is the starting point of the system, where the operator controls the throttle.

Trace the path of movement

Follow the arrows to see how the movement of the throttle lever is transmitted through the linkage system.

Identify the carburetor linkage

The final component in the system is the linkage connected to the carburetor, which controls the amount of fuel entering the engine.

Analyze the connections

Observe the types of connections between components (rigid or flexible) and their implications for movement.

Understand the function of each component

Use the labels and your knowledge of the throttle system to determine the role of each component in the operation.

Troubleshooting Throttle Linkage Issues: 4.5 Hp Mercury Outboard Throttle Linkage Diagram Pdf

A properly functioning throttle linkage is essential for safe and efficient operation of your outboard motor. The throttle linkage connects the throttle control on your boat to the carburetor on your motor, allowing you to control the engine speed. When the throttle linkage malfunctions, it can result in problems with engine acceleration, idle speed, and overall performance.

Common Problems with Throttle Linkage

The throttle linkage is a relatively simple system, but it can be susceptible to a few common problems.

- Worn or Damaged Cables:The throttle cables are responsible for transmitting the throttle position from the control to the engine. Over time, these cables can become worn or damaged, leading to sluggish throttle response or even complete failure.

- Loose or Broken Connections:The throttle linkage consists of several connections, including the throttle control, the throttle cable, the carburetor linkage, and the engine throttle arm. If any of these connections become loose or broken, the throttle linkage will not function properly.

- Binding or Sticking Parts:The throttle linkage can become stuck or bind due to dirt, corrosion, or worn parts. This can prevent the throttle from moving freely, resulting in erratic engine operation.

- Improper Adjustment:The throttle linkage needs to be properly adjusted to ensure that the throttle opens and closes smoothly and that the engine idles at the correct speed. If the linkage is not adjusted correctly, it can cause problems with engine performance.

Diagnosing Throttle Linkage Issues

A thorough inspection of the throttle linkage is crucial for identifying the source of any problems. The following checklist can help you diagnose issues:

- Inspect the Throttle Cables:Check the throttle cables for any signs of wear, damage, or fraying. Look for kinks, bends, or areas where the cable may be rubbing against other parts.

- Examine the Connections:Inspect all the connections in the throttle linkage system for looseness, corrosion, or damage. Make sure all nuts and bolts are tight and that the connections are secure.

- Check for Binding or Sticking:Move the throttle lever back and forth and observe the movement of the throttle cable and the carburetor linkage. If you notice any binding or sticking, try to identify the cause.

- Test the Throttle Response:Start the engine and slowly increase the throttle. Observe the engine speed and acceleration. If the throttle response is sluggish or erratic, there may be a problem with the throttle linkage.

Troubleshooting Tips and Techniques

Once you have identified the source of the problem, you can begin troubleshooting and resolving the issue.

- Replace Worn or Damaged Cables:If the throttle cables are worn or damaged, they should be replaced. Use high-quality cables that are compatible with your outboard motor.

- Tighten Loose Connections:If any connections are loose, tighten them securely. Ensure that all nuts and bolts are properly tightened and that the connections are secure.

- Clean and Lubricate:Clean the throttle linkage system thoroughly using a suitable cleaner and lubricant. This will remove any dirt, corrosion, or debris that may be causing binding or sticking.

- Adjust the Throttle Linkage:If the throttle linkage is not properly adjusted, it can be adjusted using the adjustment screws on the throttle control and carburetor linkage. Refer to your outboard motor’s owner’s manual for specific instructions on adjusting the throttle linkage.

Adjusting and Maintaining the Throttle Linkage

Properly adjusting and maintaining the throttle linkage on your 4.5 hp Mercury outboard is crucial for ensuring smooth and reliable operation. A well-maintained throttle linkage ensures precise control over engine speed, prevents premature wear, and maximizes engine performance.

Adjusting the Throttle Linkage

Adjusting the throttle linkage involves setting the correct idle speed and ensuring smooth throttle response. This procedure typically involves adjusting the throttle cable tension and the position of the linkage arms.

- Check the idle speed:Start the engine and allow it to warm up. The engine should idle smoothly at a specific RPM range, usually between 600 and 700 RPM. Consult your owner’s manual for the recommended idle speed for your specific model.

- Adjust the throttle cable tension:If the idle speed is too high or too low, adjust the throttle cable tension. Locate the throttle cable adjustment nut on the engine side of the cable. Turn the nut clockwise to increase tension and counterclockwise to decrease tension.

- Adjust the linkage arms:If the throttle response is not smooth, adjust the linkage arms. This typically involves adjusting the length of the linkage rods or the position of the linkage levers. Consult your owner’s manual for specific instructions on adjusting the linkage arms for your model.

- Test the throttle response:After making any adjustments, test the throttle response by gradually increasing and decreasing engine speed. Ensure the throttle operates smoothly without any hesitation or binding.

Maintaining the Throttle Linkage

Regular maintenance of the throttle linkage is essential to prevent premature wear and ensure smooth operation.

- Inspect the throttle cable:Regularly inspect the throttle cable for any signs of damage, fraying, or corrosion. Replace the cable if necessary.

- Lubricate the throttle cable:Apply a light lubricant, such as marine grease, to the throttle cable to reduce friction and prevent corrosion.

- Inspect the linkage arms:Check the linkage arms for any signs of wear, damage, or looseness. Replace any worn or damaged parts.

- Lubricate the linkage pivots:Apply a light lubricant, such as marine grease, to the linkage pivots to reduce friction and prevent corrosion.

- Clean the linkage:Regularly clean the throttle linkage with a soft brush and a mild detergent to remove dirt and debris.

Recommendations for Regular Maintenance and Lubrication

To ensure optimal performance and longevity of your throttle linkage, follow these recommendations:

Lubricate the throttle cable and linkage pivots every 50 hours of operation or before each boating season.

Inspect the throttle cable and linkage arms for any signs of wear or damage at least once a year.

Replace the throttle cable every 5 years or sooner if it shows signs of wear or damage.

Safety Precautions

Working with the throttle linkage of a 4.5 hp Mercury outboard motor requires caution to prevent accidents and potential injuries. Improper handling or adjustments can lead to engine failure, loss of control, or even serious accidents.

Safety Precautions for Throttle Linkage Maintenance

It is crucial to prioritize safety when working with the throttle linkage. The following precautions should be observed during troubleshooting and maintenance:

- Always disconnect the battery before working on the throttle linkage. This will prevent accidental ignition of the engine while working on electrical components.

- Wear appropriate safety gear, including eye protection, gloves, and closed-toe shoes. This will protect you from potential hazards such as sharp edges, moving parts, and spilled fluids.

- Work in a well-ventilated area to avoid exposure to fumes from gasoline or other engine fluids.

- Ensure the engine is in neutral gear and the propeller is not spinning before working on the throttle linkage.

- Never operate the engine while the throttle linkage is disconnected or malfunctioning. This can result in uncontrolled acceleration and potential accidents.

- If you are unsure about any aspect of the throttle linkage, consult a qualified marine mechanic. Incorrect adjustments or repairs can lead to serious consequences.

Potential Hazards Associated with Throttle Linkage Malfunctions

A malfunctioning throttle linkage can pose several hazards:

- Loss of engine control:A faulty throttle linkage can prevent the engine from accelerating or decelerating properly, leading to a loss of control. This can be particularly dangerous in high-traffic areas or when navigating obstacles.

- Unintentional acceleration:In some cases, a malfunctioning throttle linkage can cause the engine to accelerate unexpectedly. This can lead to a sudden increase in speed and potential collisions.

- Engine damage:A misadjusted or damaged throttle linkage can cause the engine to run at an incorrect speed, leading to overheating and potential damage.

- Personal injury:Improper handling of the throttle linkage or a malfunctioning system can result in injuries from moving parts, sharp edges, or spilled fluids.

Parts and Replacement Information

This section provides information about the common parts found in the throttle linkage system of a 4.5 hp Mercury outboard motor, and where to find replacement parts. Understanding the components and their functions is crucial for troubleshooting and maintaining the throttle system.

Common Parts

The throttle linkage system of a 4.5 hp Mercury outboard motor typically includes the following components:

- Throttle Cable: This cable connects the throttle control on the boat to the carburetor, allowing you to adjust the engine speed.

- Throttle Lever: The throttle lever is attached to the throttle cable and allows you to adjust the engine speed by moving the lever forward or backward.

- Throttle Arm: The throttle arm is connected to the carburetor and is moved by the throttle cable to adjust the engine speed.

- Throttle Return Spring: This spring helps to return the throttle lever to its idle position when you release the throttle.

- Throttle Stop: This component prevents the throttle from opening too far, ensuring the engine doesn’t over-rev.

- Throttle Linkage Pins: These pins connect the different parts of the throttle linkage system, allowing for smooth movement.

Obtaining Replacement Parts

Replacement parts for the throttle linkage system can be obtained from several sources, including:

- Mercury Authorized Dealers: These dealers offer genuine Mercury parts, ensuring compatibility and quality.

- Online Retailers: Many online retailers specialize in marine parts, offering a wide selection of components for Mercury outboards.

- Used Parts Suppliers: If you’re looking for a more affordable option, you can find used parts from specialized suppliers.

Compatibility and Specifications

When replacing throttle linkage parts, it is crucial to ensure compatibility with your specific Mercury outboard model. Parts specifications can vary depending on the year and model of your engine. Consult your owner’s manual or contact a Mercury dealer for accurate information about the correct parts for your engine.

Additional Resources

This section provides you with a comprehensive list of resources that can help you further your understanding of Mercury outboard throttle linkage systems. From official manuals to helpful online communities, you’ll find everything you need to troubleshoot, maintain, and repair your outboard motor.

Mercury Outboard Manuals and Documentation, 4.5 hp mercury outboard throttle linkage diagram pdf

Mercury Marine offers a wide range of manuals and documentation for its outboard motors. These resources are invaluable for understanding the inner workings of your motor and performing maintenance tasks.

- Official Mercury Marine Website:The Mercury Marine website is a treasure trove of information. You can find owner’s manuals, service manuals, parts diagrams, and technical bulletins for all Mercury outboard models. The website also includes a comprehensive search function that allows you to find specific information quickly.

- Mercury Outboard Parts Catalog:The Mercury Outboard Parts Catalog provides detailed information on every part of your outboard motor. This catalog is essential for identifying and ordering replacement parts.

- Mercury Outboard Service Manuals:Service manuals contain detailed instructions on how to perform repairs and maintenance tasks on your outboard motor.

These manuals are typically available through authorized Mercury dealers.

Online Forums and Communities

Connecting with other Mercury outboard owners is a great way to get advice, share experiences, and troubleshoot problems. Many online forums and communities are dedicated to Mercury outboards, providing a valuable platform for information exchange.

- iBoats Forum:iBoats is a popular online forum for boaters and marine enthusiasts. The forum features a dedicated section for Mercury outboards where users can ask questions, share tips, and discuss troubleshooting techniques.

- Mercury Marine Owners’ Forum:The Mercury Marine Owners’ Forum is a dedicated online community for Mercury outboard owners.

This forum provides a platform for discussing a wide range of topics, including maintenance, repair, and general outboard knowledge.

- Other Marine Forums:Numerous other marine forums and communities exist online. Search for forums specific to boating, marine engines, or outboard motors to find a community that suits your needs.

YouTube Videos and Tutorials

YouTube is an excellent resource for finding instructional videos and tutorials on a wide range of topics, including Mercury outboard maintenance and repair.

- Mercury Marine Official YouTube Channel:The official Mercury Marine YouTube channel features a collection of videos on various topics, including product demonstrations, maintenance tips, and troubleshooting guides.

- Independent Marine Mechanics:Many independent marine mechanics and enthusiasts create YouTube videos showcasing repair techniques, troubleshooting tips, and general outboard knowledge.

Search for videos specific to your Mercury outboard model or the issue you’re facing.

Mercury Outboard Support and Technical Assistance

If you need direct assistance from Mercury Marine, you can contact their customer support team or locate an authorized dealer in your area.

- Mercury Marine Customer Support:Contact Mercury Marine customer support by phone, email, or online chat for assistance with your outboard motor. You can find their contact information on their official website.

- Authorized Mercury Dealers:Authorized Mercury dealers provide a wide range of services, including maintenance, repair, and parts sales.

You can locate an authorized dealer near you using the dealer locator tool on the Mercury Marine website.

Case Studies and Real-World Examples

Applying the throttle linkage diagram in practical scenarios can be extremely helpful for diagnosing and resolving issues with your Mercury outboard engine. Understanding the components, their interactions, and common failure points allows you to approach troubleshooting systematically and efficiently.

Real-World Troubleshooting Scenarios

The throttle linkage diagram provides a visual roadmap for identifying the source of problems related to throttle response, engine speed control, and overall performance. Here are some common scenarios where the diagram proves invaluable:

- Engine Won’t Idle Properly:If your engine struggles to maintain a stable idle speed, the diagram can help you trace the issue back to a faulty idle adjustment screw, a disconnected or worn linkage component, or a problem with the throttle cable itself.

- Throttle Sticks or Feels Sluggish:A stuck throttle can be caused by a variety of factors, including a binding linkage, a seized throttle cable, or a problem with the throttle control mechanism. By carefully examining the diagram, you can pinpoint the source of the issue and take appropriate action.

- Engine Revs Up Unexpectedly:An engine that unexpectedly revs up can be a sign of a broken or misaligned throttle linkage component. The diagram can help you identify the specific part that is causing the problem and guide you in making the necessary repairs.

- Engine Doesn’t Respond to Throttle Input:If your engine fails to respond to throttle input, it could be a problem with the throttle linkage, the throttle cable, or even the engine’s internal components. The diagram can help you isolate the problem and determine if it’s a linkage-related issue or something more serious.

Understanding the workings of a 4.5 hp Mercury outboard throttle linkage is essential for smooth operation and optimal performance. While a serpentine belt diagram for a 2017 Laramie Dodge 5.7 Hemi might seem unrelated, both illustrate the importance of correctly routed and tensioned components for proper engine function.

The throttle linkage diagram helps identify the correct positioning and adjustment of the throttle cable, while the serpentine belt diagram ensures that the engine’s accessories are adequately powered.

Future Developments and Trends

The field of outboard engine technology is constantly evolving, with advancements in materials, electronics, and design leading to more efficient, powerful, and user-friendly engines. These advancements also impact the throttle linkage systems, pushing them to become more reliable, precise, and integrated with the overall engine control system.

Advancements in Throttle Linkage Technology

The future of throttle linkage technology in outboard engines is likely to see a shift towards more electronically controlled and integrated systems. This will lead to smoother, more precise throttle response and improved fuel efficiency.

- Electronic Throttle Control (ETC):ETC systems replace traditional mechanical linkages with electronic sensors and actuators. This allows for more precise throttle control, eliminating play and lag associated with mechanical systems. ETC also enables features like cruise control and engine synchronization, enhancing the overall user experience.

- Integrated Throttle and Shift Systems:The integration of throttle and shift control into a single system simplifies operation and reduces the number of mechanical components. This leads to increased reliability and reduces the risk of malfunctions. Examples include the “SmartCraft” systems offered by Mercury Marine, which combine throttle, shift, and engine monitoring into a single digital interface.

- Advanced Materials:The use of lightweight and durable materials like composites and high-strength alloys will enhance the lifespan and performance of throttle linkage components. These materials also contribute to reduced weight, improving fuel efficiency and overall engine performance.

Emerging Trends in Outboard Engine Design and Maintenance

The outboard engine industry is experiencing a number of trends that will impact throttle linkage design and maintenance in the future.

- Increased Automation:Outboard engines are becoming increasingly automated, with features like automatic trim and tilt, and even self-diagnostics. This trend will likely lead to more sophisticated throttle linkage systems that are seamlessly integrated with these automated functions.

- Focus on Sustainability:The industry is focusing on reducing emissions and improving fuel efficiency. This will require advancements in throttle linkage technology that optimize engine performance and reduce fuel consumption. For example, ETC systems can optimize fuel delivery based on engine load and operating conditions.

- Remote Control and Connectivity:The use of remote control systems and connectivity features like smartphone apps is becoming increasingly common. These technologies will require throttle linkage systems that can be seamlessly integrated with remote control units and provide real-time engine data to the user.

Future of 4.5 HP Mercury Outboards

While the 4.5 HP Mercury outboard is a reliable and popular option for small boats, the future of this model is likely to be impacted by evolving trends in the industry.

- Potential for Increased Power and Features:While maintaining its compact size and affordability, the 4.5 HP Mercury outboard may see incremental increases in power and the addition of features like electric start and remote control options. This will cater to a wider range of boating needs and preferences.

- Focus on Durability and Reliability:Mercury is known for its durable and reliable outboards. The future of the 4.5 HP model will likely see further improvements in materials and construction, ensuring its longevity and performance even in demanding conditions.

- Emphasis on Ease of Use and Maintenance:The simplicity of the 4.5 HP Mercury outboard is one of its strengths. Future iterations will likely maintain this ease of use while incorporating features that simplify maintenance and troubleshooting.

Frequently Asked Questions

Where can I find a 4.5 HP Mercury outboard throttle linkage diagram PDF?

You can typically find these diagrams online on manufacturer websites, boating forums, or specialized parts websites. You can also consult your Mercury outboard owner’s manual.

What if I can’t find a specific diagram for my 4.5 HP Mercury outboard?

If you can’t find a specific diagram for your model, you can try contacting Mercury customer support for assistance. They might have a digital copy available or direct you to a resource that offers a suitable diagram.

Is it safe to work on the throttle linkage myself?

While working on the throttle linkage can be done by yourself, it’s crucial to prioritize safety. Consult the owner’s manual and take necessary precautions before attempting any adjustments or repairs.