2003 oldsmobile aurora diagram under hood diagram – The 2003 Oldsmobile Aurora Diagram: Under the Hood provides a comprehensive visual guide to the inner workings of this classic car. Understanding the layout of the engine compartment is crucial for any owner who wants to perform routine maintenance, troubleshoot issues, or even just appreciate the engineering behind this American icon.

This guide offers a detailed breakdown of each major component, including the engine, cooling system, electrical system, fuel system, exhaust system, braking system, and suspension system. Each section provides clear descriptions, diagrams, and practical tips to help you navigate the under-hood space with confidence.

Introduction

The 2003 Oldsmobile Aurora was a mid-size luxury sedan that offered a blend of performance and comfort. It was known for its sleek design, spacious interior, and powerful engine options. Under the hood, the Aurora housed a 3.5-liter V6 engine, generating a respectable 215 horsepower.

Understanding the layout of the engine compartment is crucial for performing routine maintenance, addressing repairs, and troubleshooting potential issues. A clear visual representation of the engine components and their positions helps in identifying parts, accessing them easily, and ensuring efficient and accurate work.

Engine Components

The engine compartment of the 2003 Oldsmobile Aurora houses a variety of components, each playing a vital role in the vehicle’s operation. The engine, the heart of the car, is surrounded by various supporting systems.

- Engine:The 3.5-liter V6 engine is the primary power source of the Aurora. It is located at the front of the vehicle, with the intake manifold facing the front and the exhaust manifold facing the rear.

- Transmission:The transmission, connected to the engine, transmits power to the wheels. It is located behind the engine and is responsible for gear shifting.

- Cooling System:The cooling system ensures the engine operates at the optimal temperature. It includes the radiator, coolant hoses, thermostat, and water pump.

- Electrical System:The electrical system provides power to various components, including the engine, lights, and accessories. It includes the battery, alternator, starter, and wiring harnesses.

- Fuel System:The fuel system delivers fuel to the engine. It includes the fuel tank, fuel pump, fuel lines, and fuel injectors.

- Exhaust System:The exhaust system removes harmful gases from the engine. It includes the exhaust manifolds, catalytic converter, muffler, and tailpipe.

- Air Intake System:The air intake system provides clean air to the engine. It includes the air filter, intake manifold, and throttle body.

Engine Compartment Overview

The engine compartment of the 2003 Oldsmobile Aurora is a complex and well-organized space that houses the vehicle’s powertrain and essential systems. Understanding the layout and components of this area is crucial for basic maintenance, troubleshooting, and even appreciating the car’s engineering.

Engine Compartment Layout

The engine compartment of the 2003 Oldsmobile Aurora features a traditional front-engine, front-wheel-drive configuration. The engine is positioned towards the front of the compartment, with the radiator positioned in front of it. The battery is usually located on the driver’s side, while the air intake is situated near the front of the compartment.

Engine Compartment Components

The engine compartment is home to a variety of essential components that work together to power and maintain the vehicle. The following table provides a detailed overview of these components, their locations, functions, and maintenance tips.

The 2003 Oldsmobile Aurora under hood diagram, a faded relic of a bygone era, whispers of a time when American cars were built to last. Its intricate lines, now worn with age, speak of a past filled with long drives and family adventures.

Yet, even as the Aurora fades into memory, the spirit of mechanical innovation lives on, as seen in the modern 2015 Jeep Cherokee 3.2L serpentine belt diagram , a testament to the enduring fascination with engines and their intricate workings.

Just like the Aurora’s diagram, the Cherokee’s serpentine belt diagram offers a glimpse into the complex ballet of components that bring a vehicle to life, a reminder that even in the age of electric vehicles, the allure of a well-tuned engine remains.

| Component | Location | Function | Maintenance Tips |

|---|---|---|---|

| Engine | Front of the compartment | Provides power to the vehicle | Regular oil changes, air filter replacement, and coolant checks are essential for optimal engine performance. |

| Radiator | In front of the engine | Cools the engine by circulating coolant | Regular coolant flushes and inspections for leaks are crucial for maintaining proper engine temperature. |

| Battery | Driver’s side of the compartment | Provides electrical power to the vehicle | Ensure the battery terminals are clean and secure. Check the battery’s fluid level and charge periodically. |

| Air Intake | Near the front of the compartment | Draws in air for combustion | Regular air filter replacement is crucial for maintaining proper engine performance and fuel efficiency. |

| Alternator | Mounted on the engine | Generates electrical power for the vehicle | Ensure the alternator belt is in good condition and tensioned properly. |

| Starter | Mounted on the engine | Starts the engine | Inspect the starter motor and wiring for any signs of damage or wear. |

| Fuel Lines | Run from the fuel tank to the engine | Deliver fuel to the engine | Inspect fuel lines for leaks and ensure they are properly secured. |

| Coolant Hoses | Connect the radiator to the engine | Circulate coolant through the engine | Inspect coolant hoses for leaks, cracks, or signs of wear. |

| Air Conditioning System | Located in the engine compartment | Provides cool air to the cabin | Have the air conditioning system serviced regularly to ensure proper operation and refrigerant levels. |

| Power Steering System | Located in the engine compartment | Assists in steering the vehicle | Check the power steering fluid level and ensure the system is free of leaks. |

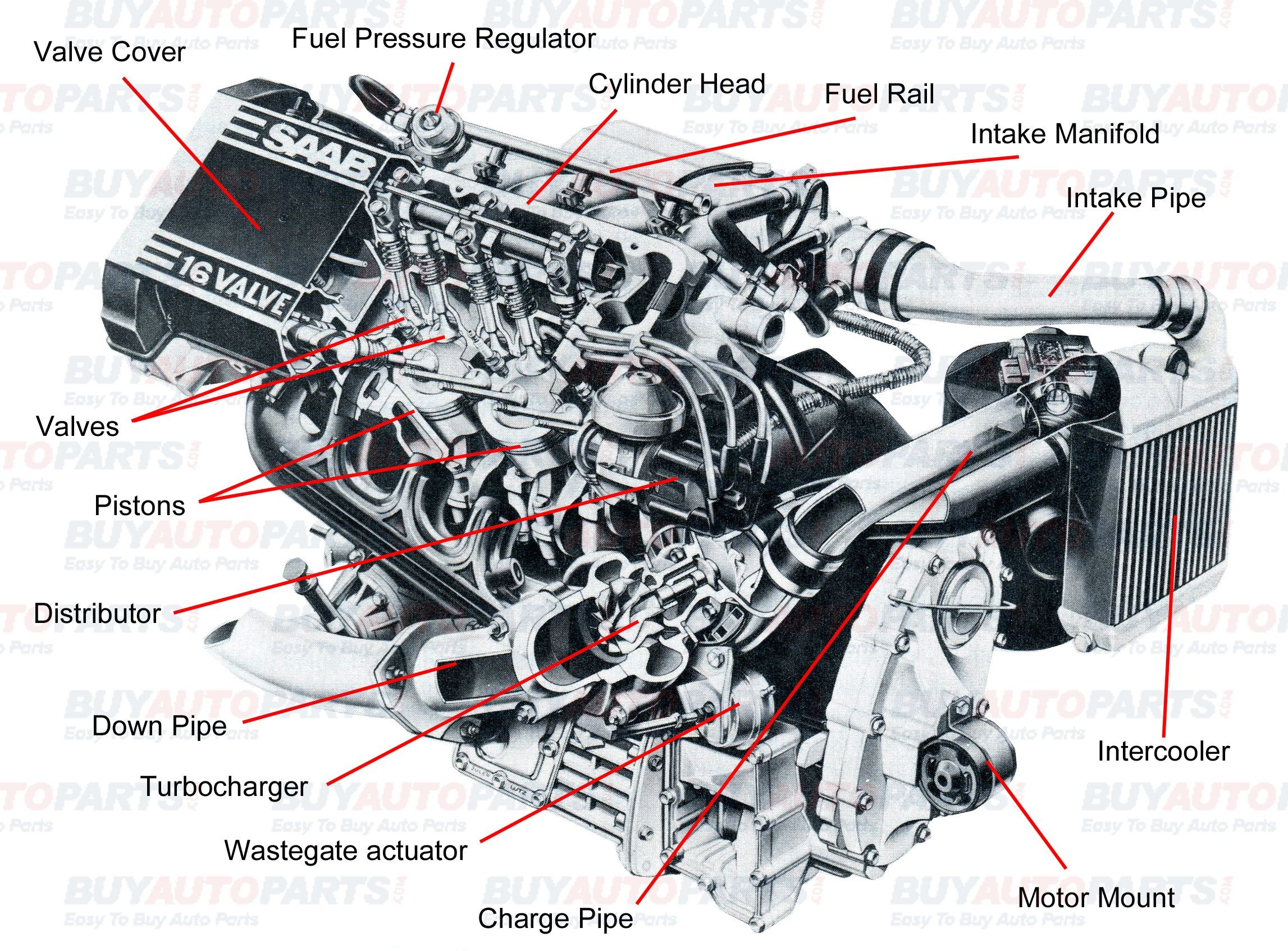

Engine Diagram

The engine is the heart of the Oldsmobile Aurora, and understanding its components is crucial for maintenance and troubleshooting. This section provides a detailed diagram of the engine, highlighting key components and their functions.

Engine Components

The engine of the 2003 Oldsmobile Aurora is a powerful and complex system. It consists of numerous components that work together to generate power. Here’s a breakdown of some of the most important parts:

- Cylinder Head:This component forms the top of the combustion chamber, where the fuel-air mixture is ignited. It contains valves that control the flow of air and exhaust gases.

- Camshaft:Located within the cylinder head, the camshaft controls the opening and closing of the valves. It is driven by the crankshaft, which rotates at half the speed of the crankshaft.

- Crankshaft:This rotating shaft converts the linear motion of the pistons into rotational motion, which is used to power the vehicle. It is connected to the pistons via connecting rods.

- Intake Manifold:This component delivers the air-fuel mixture to the cylinders. It typically includes a throttle body, which controls the amount of air entering the engine.

Cooling System

The cooling system of your 2003 Oldsmobile Aurora is crucial for maintaining optimal engine performance and preventing overheating. It’s like a vital organ in your car, ensuring that your engine stays cool and happy.

Cooling System Components

The cooling system consists of several key components that work together to keep your engine at the right temperature. These components are like the parts of a puzzle, each playing a crucial role in keeping the engine running smoothly.

- Radiator: The radiator is like the car’s air conditioner, responsible for dissipating heat from the coolant. It’s a large, rectangular container with fins that help transfer heat from the coolant to the air passing through it.

- Thermostat: The thermostat acts like a temperature regulator, controlling the flow of coolant between the engine and the radiator. It opens when the engine reaches operating temperature, allowing coolant to circulate through the radiator and cool down. When the engine is cold, the thermostat remains closed, keeping the coolant within the engine to help it warm up faster.

- Water Pump: The water pump is like the heart of the cooling system, circulating the coolant throughout the engine and radiator. It’s a mechanical device that uses a belt or chain to drive a impeller, which pumps the coolant through the system.

- Hoses: The hoses are like the veins and arteries of the cooling system, connecting the various components and allowing coolant to flow freely. They’re made of durable rubber or plastic and are designed to withstand high temperatures and pressure.

Checking Coolant Level

Maintaining the correct coolant level is essential for preventing engine overheating. Here’s how to check the coolant level in your 2003 Oldsmobile Aurora:

- Locate the Coolant Reservoir: The coolant reservoir is usually a translucent plastic container located near the front of the engine compartment. It’s often labeled with a “Coolant” or “Radiator” symbol.

- Check the Coolant Level: With the engine cold, carefully remove the reservoir cap. Observe the coolant level, which should be between the “Full” and “Low” marks on the reservoir. If the level is low, add more coolant of the correct type.

Refer to your owner’s manual for the recommended coolant type for your vehicle.

Routine Maintenance

Regular maintenance is crucial for keeping your cooling system in tip-top shape. Here are some key maintenance tasks:

- Flush and Replace Coolant: It’s recommended to flush and replace the coolant every 2-3 years or 30,000 miles. This helps to remove contaminants and ensure proper cooling system performance.

- Inspect Hoses: Regularly inspect hoses for cracks, leaks, or signs of wear. Replace any damaged hoses promptly to prevent coolant leaks.

- Check the Water Pump: Listen for any unusual noises from the water pump, such as whining or grinding. If you hear any unusual sounds, it’s a sign that the water pump may be failing and needs to be replaced.

Electrical System

The electrical system in the 2003 Oldsmobile Aurora is responsible for powering all the vehicle’s electrical components, from the lights and radio to the engine and transmission. It’s like the nervous system of the car, ensuring everything works together smoothly.

Components of the Electrical System

The electrical system of the 2003 Oldsmobile Aurora is made up of various interconnected components, each playing a crucial role in the car’s operation.

- Battery: The battery is the heart of the electrical system, providing the initial power to start the engine and powering electrical components when the engine is off. It stores electrical energy in a chemical form, releasing it as needed.

- Alternator: The alternator is the engine’s power source, generating electrical energy while the engine is running. This energy is used to charge the battery and power all the electrical components.

- Starter: The starter motor uses electricity from the battery to turn the engine crankshaft, initiating the combustion process. It acts like a powerful electric motor, providing the initial force needed to start the engine.

- Wiring Harness: The wiring harness is a network of wires and connectors that distribute electrical power and signals throughout the vehicle. It connects all the electrical components, allowing them to communicate and function correctly.

- Fuses and Circuit Breakers: These safety devices protect the electrical system from overload. They act as a barrier, interrupting the flow of electricity if a circuit draws too much current, preventing damage to the wiring and components.

Troubleshooting Electrical Issues

Electrical issues can be tricky to diagnose, but with some basic knowledge and a systematic approach, you can often pinpoint the problem.

- Check the Battery: A weak or dead battery can cause various electrical problems. Check the battery terminals for corrosion and ensure the battery is properly secured. Use a voltmeter to test the battery voltage.

- Inspect the Alternator: A faulty alternator can’t charge the battery, leading to electrical problems. Check the alternator belt for wear and tear, and use a voltmeter to test the alternator output.

- Examine the Wiring Harness: Damaged or corroded wires in the wiring harness can disrupt the flow of electricity. Inspect the harness for any visible damage and check the connectors for corrosion.

- Test Fuses and Circuit Breakers: A blown fuse or tripped circuit breaker can prevent electrical components from working. Use a fuse tester to check the fuses and reset any tripped circuit breakers.

- Consult a Professional: If you’re unable to diagnose the problem, it’s best to consult a qualified mechanic. They have the expertise and tools to identify and fix complex electrical issues.

Fuel System

The fuel system is the lifeline of your 2003 Oldsmobile Aurora’s engine, responsible for delivering the vital fuel that keeps it running smoothly. It’s a complex network of components working together to ensure a constant supply of fuel to the engine.

Fuel System Components, 2003 oldsmobile aurora diagram under hood diagram

The fuel system comprises several key components that play crucial roles in delivering fuel to the engine:

- Fuel Tank:The fuel tank stores the gasoline for the engine. It’s usually located in the rear of the vehicle.

- Fuel Pump:The fuel pump is an electric motor that draws fuel from the tank and pushes it through the fuel lines to the engine.

- Fuel Lines:Fuel lines are hoses that carry fuel from the tank to the engine. They are made of durable materials to withstand the pressure and temperature of the fuel.

- Fuel Filter:The fuel filter traps dirt and debris from the fuel, preventing them from reaching the engine and causing damage.

- Fuel Injectors:Fuel injectors are small, precisely controlled valves that spray fuel into the engine’s cylinders at the right time and in the right amount.

Fuel System Operation

The fuel system works in a sequence to deliver fuel to the engine. When you turn the ignition key, the fuel pump activates and starts drawing fuel from the tank. The fuel flows through the fuel lines and filter, cleaning it before it reaches the fuel injectors.

The fuel injectors then spray the fuel into the engine’s cylinders, where it mixes with air and ignites, creating power.

Fuel System Maintenance

Regular maintenance of the fuel system is essential to ensure optimal engine performance and longevity. Here are some key maintenance tasks:

- Fuel Filter Replacement:The fuel filter should be replaced periodically, as recommended by the manufacturer. A clogged filter can restrict fuel flow, leading to engine problems.

- Fuel Line Inspection:Regularly inspect the fuel lines for leaks, cracks, or damage. Leaks can pose a fire hazard, and damaged lines can lead to fuel loss.

- Fuel Injector Cleaning:Over time, fuel injectors can become clogged with deposits, affecting fuel flow and engine performance. Professional cleaning can restore injector efficiency.

- Fuel System Additives:Using fuel system additives can help clean and maintain the fuel system, preventing deposits and improving fuel efficiency.

Fuel Leak Detection

Fuel leaks can be dangerous and costly. Here’s how to check for leaks:

- Visual Inspection:Carefully inspect the fuel lines, fuel tank, and fuel injectors for any signs of leakage, such as dripping fuel or wet spots.

- Fuel Odor:If you smell gasoline, it could indicate a fuel leak. Follow your nose to locate the source of the odor.

- Fuel Gauge:If the fuel gauge is dropping rapidly, it could be a sign of a fuel leak.

Exhaust System

The exhaust system is a vital part of your Oldsmobile Aurora’s engine, responsible for channeling harmful combustion byproducts away from the engine and into the atmosphere. It plays a crucial role in reducing noise and emissions, contributing to a smoother and quieter driving experience.

Exhaust System Components

The exhaust system is comprised of several interconnected components, each with a specific function:

- Exhaust Manifold: This component is directly attached to the engine and collects exhaust gases from each cylinder. It acts as the starting point for the exhaust system.

- Catalytic Converter: Located downstream from the exhaust manifold, the catalytic converter plays a crucial role in reducing harmful emissions by converting pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances. This process involves chemical reactions facilitated by precious metals within the converter.

- Muffler: This component is designed to reduce the noise produced by the exhaust gases. It typically contains a series of chambers and baffles that absorb sound waves, making the engine quieter.

- Tailpipe: This is the final component of the exhaust system, extending from the muffler to the rear of the vehicle. It releases the exhaust gases into the atmosphere.

Identifying Exhaust System Problems

A faulty exhaust system can manifest in various ways, indicating the need for attention. Here are some common signs to watch out for:

- Loud Exhaust Noise: An excessively loud exhaust noise, especially when accelerating or idling, could indicate a leak in the system. This can be caused by a cracked or rusted component, loose clamps, or a damaged muffler.

- Unusual Odors: A strong, pungent odor emanating from the exhaust can be a sign of a problem with the catalytic converter or other components. For example, a sweet, sickly smell might indicate a malfunctioning catalytic converter, while a strong fuel-like odor could suggest a leak in the fuel system.

- Reduced Engine Performance: A clogged catalytic converter can restrict exhaust flow, leading to reduced engine power and performance. Other problems in the exhaust system can also contribute to this issue.

- Visible Smoke: Smoke coming from the exhaust, particularly black or blue smoke, can indicate problems with combustion or fuel delivery. However, white smoke could be a sign of a coolant leak, indicating a more serious issue.

Braking System: 2003 Oldsmobile Aurora Diagram Under Hood Diagram

The braking system is a vital safety feature in any vehicle, and the Oldsmobile Aurora is no exception. It’s responsible for slowing down and stopping the car, preventing accidents and ensuring safe driving.

Components of the Braking System

The braking system of the Oldsmobile Aurora consists of several key components that work together to bring the vehicle to a stop.

- Brake Master Cylinder: This is the heart of the hydraulic braking system. It converts the pressure applied to the brake pedal into hydraulic pressure, which is then transmitted to the brake calipers.

- Brake Calipers: These are located at each wheel and contain pistons that push the brake pads against the brake rotors.

- Brake Pads: These are friction materials that create the force that slows down the vehicle when pressed against the brake rotors.

- Brake Rotors: These are discs that are attached to the wheels and are pressed against by the brake pads.

- Brake Lines: These are tubes that carry the hydraulic fluid from the master cylinder to the calipers.

- Brake Booster: This is a vacuum-powered device that assists the driver in applying brake pressure.

Inspecting and Maintaining the Braking System

Regular inspection and maintenance are crucial for ensuring the braking system is in optimal working condition.

- Check Brake Fluid Level: The brake fluid level should be checked regularly and topped off as needed. Low brake fluid can indicate a leak or other problems.

- Inspect Brake Pads: Worn brake pads need to be replaced. The thickness of the brake pads should be checked regularly.

- Inspect Brake Rotors: Check for cracks, grooves, or excessive wear on the brake rotors.

- Test Brake Pedal Feel: The brake pedal should feel firm and responsive. If the pedal feels spongy or soft, there may be a problem with the braking system.

- Have Brakes Inspected by a Professional: It is recommended to have the braking system inspected by a qualified mechanic at least once a year.

Suspension System

The suspension system in your 2003 Oldsmobile Aurora plays a crucial role in providing a comfortable ride and ensuring optimal handling. It acts as a buffer between the vehicle and the road, absorbing bumps and dips to keep the car stable and prevent excessive vibrations from reaching the cabin.

Components of the Suspension System

The suspension system is comprised of several key components working in unison to achieve its function. These components include:

- Struts:Struts are a combination of a shock absorber and a spring, providing both damping and support. They are responsible for controlling the vertical movement of the wheels and maintaining stability.

- Shock Absorbers:Shock absorbers are designed to dampen the vibrations caused by road imperfections. They work by converting kinetic energy into heat, preventing the car from bouncing excessively.

- Springs:Springs are responsible for supporting the weight of the vehicle and returning the wheels to their original position after being compressed by bumps or dips.

- Control Arms:Control arms connect the wheels to the vehicle’s frame, providing lateral support and controlling the wheel’s movement. They help maintain the proper alignment of the wheels and ensure smooth handling.

Recognizing Signs of Suspension Problems

Knowing the signs of a potential suspension problem can help you address it promptly and prevent further damage. Common signs include:

- Uneven tire wear:If the tires are wearing unevenly, it could indicate a problem with the alignment, suspension components, or both.

- Excessive bouncing or swaying:When driving over bumps or uneven surfaces, the car should not bounce excessively. If it does, it could be a sign of worn shock absorbers or springs.

- Noises during driving:Clunking, rattling, or grinding noises, especially when driving over bumps or turning, could indicate loose or worn suspension components.

- Vehicle pulling to one side:If the vehicle pulls to one side while driving straight, it could be a sign of misaligned wheels or worn suspension components.

- Steering wheel vibration:Vibration in the steering wheel, especially at higher speeds, could indicate a problem with the suspension, tires, or wheel bearings.

Troubleshooting Common Issues

The 2003 Oldsmobile Aurora, like any car, can experience its fair share of issues. Understanding common problems and how to troubleshoot them can save you time, money, and frustration. This section will guide you through some of the most frequent issues and provide practical steps to diagnose and potentially fix them.

Engine Problems

Engine problems are among the most common issues you might encounter with your 2003 Oldsmobile Aurora. These problems can range from minor annoyances to major breakdowns.

- Engine Stalling:A common symptom of a faulty ignition system, fuel system, or vacuum leak. Check the spark plugs, wires, distributor cap, and rotor. Also, inspect the fuel pump, fuel filter, and fuel lines for leaks or blockages.

- Rough Idle:Can be caused by a variety of issues, including dirty fuel injectors, a faulty oxygen sensor, a clogged air filter, or a vacuum leak. Start by cleaning the fuel injectors and replacing the air filter. If the problem persists, consider checking the oxygen sensor and inspecting for vacuum leaks.

- Engine Misfire:Often indicated by a rough running engine, reduced power, or a check engine light. This can be caused by faulty spark plugs, wires, or ignition coils. Check the spark plugs and wires for wear and tear, and replace any faulty components.

Transmission Problems

The transmission is a vital component of your car, and issues can significantly impact drivability.

- Transmission Slipping:A common sign of a failing transmission. This can be caused by low transmission fluid, a worn-out clutch pack, or a faulty transmission control module. Check the transmission fluid level and condition. If it’s low or dirty, replace it.

If the problem persists, a professional inspection might be needed.

- Transmission Not Shifting:Can be caused by a variety of issues, including a faulty transmission control module, a clogged transmission filter, or a malfunctioning solenoid. If the transmission isn’t shifting properly, have it inspected by a qualified mechanic.

Electrical Problems

Electrical problems can be tricky to diagnose and can affect various systems in your car.

- Battery Issues:A dead or failing battery can cause a range of problems, from difficulty starting the car to malfunctioning electrical components. Check the battery terminals for corrosion and ensure they are clean and tight. If the battery is old or showing signs of wear, consider replacing it.

- Alternator Problems:A faulty alternator can lead to a dead battery and electrical problems. Check the alternator belt for wear and tear, and ensure it’s properly tensioned. If the alternator is failing, it will need to be replaced.

- Electrical Short Circuit:Can cause a variety of problems, including blown fuses, malfunctioning electrical components, and even fires. If you suspect an electrical short, disconnect the battery and have the issue inspected by a qualified mechanic.

Braking System Problems

A properly functioning braking system is crucial for safe driving.

- Brake Pedal Going to the Floor:This can indicate a loss of brake fluid, a leak in the brake lines, or a problem with the master cylinder. Check the brake fluid level and inspect the brake lines for leaks. If the problem persists, have the brakes inspected by a qualified mechanic.

- Squealing Brakes:Often caused by worn-out brake pads or rotors. Inspect the brake pads and rotors for wear and tear. If they are worn, they will need to be replaced.

- Brake Vibration:Can be caused by warped brake rotors or uneven wear on the brake pads. Inspect the brake rotors for warping and replace them if necessary. Also, check the brake pads for uneven wear and replace them if needed.

Suspension Problems

The suspension system is responsible for providing a smooth ride and handling.

- Uneven Tire Wear:Can be caused by a variety of suspension issues, including worn-out shocks, struts, or control arm bushings. Inspect the suspension components for wear and tear. If any parts are worn, they will need to be replaced.

- Clunking Noise:Can be caused by worn-out suspension components, such as ball joints, tie rod ends, or control arm bushings. Inspect the suspension components for wear and tear. If any parts are worn, they will need to be replaced.

- Vehicle Pulling to One Side:Can be caused by a variety of suspension issues, including worn-out suspension components, misaligned wheels, or uneven tire pressure. Inspect the suspension components for wear and tear. If any parts are worn, they will need to be replaced. Also, have the wheels aligned and check the tire pressure.

FAQ Corner

What type of engine does the 2003 Oldsmobile Aurora have?

The 2003 Oldsmobile Aurora is equipped with a 3.5L V6 engine.

Where is the fuse box located in a 2003 Oldsmobile Aurora?

The fuse box is typically located in the engine compartment, near the battery.

How often should I change the oil in a 2003 Oldsmobile Aurora?

It’s recommended to change the oil every 3,000-5,000 miles, depending on driving conditions.

What is the average fuel economy of a 2003 Oldsmobile Aurora?

The 2003 Oldsmobile Aurora typically gets around 18-22 mpg.

What are some common problems with the 2003 Oldsmobile Aurora?

Some common issues include electrical problems, transmission problems, and engine overheating.