1992 XJ Clutch Assembly Diagram PDF, a digital treasure map for your Jeep Cherokee’s vital transmission system, unravels the intricacies of the clutch assembly. This diagram acts as a blueprint, illuminating the components, their functions, and the complex dance they perform to transfer power from the engine to the wheels.

Imagine a world where you can visualize every nut and bolt, every wire and hose, all interconnected in a symphony of motion. The 1992 XJ Clutch Assembly Diagram PDF provides that visual clarity, empowering you to understand the heart of your vehicle.

The 1992 XJ Cherokee, a rugged and reliable SUV, has earned its place in automotive history. Its clutch assembly, a critical component for smooth gear changes, plays a pivotal role in its performance. Understanding this intricate system is essential for any owner who desires to maintain their vehicle’s longevity and ensure a satisfying driving experience.

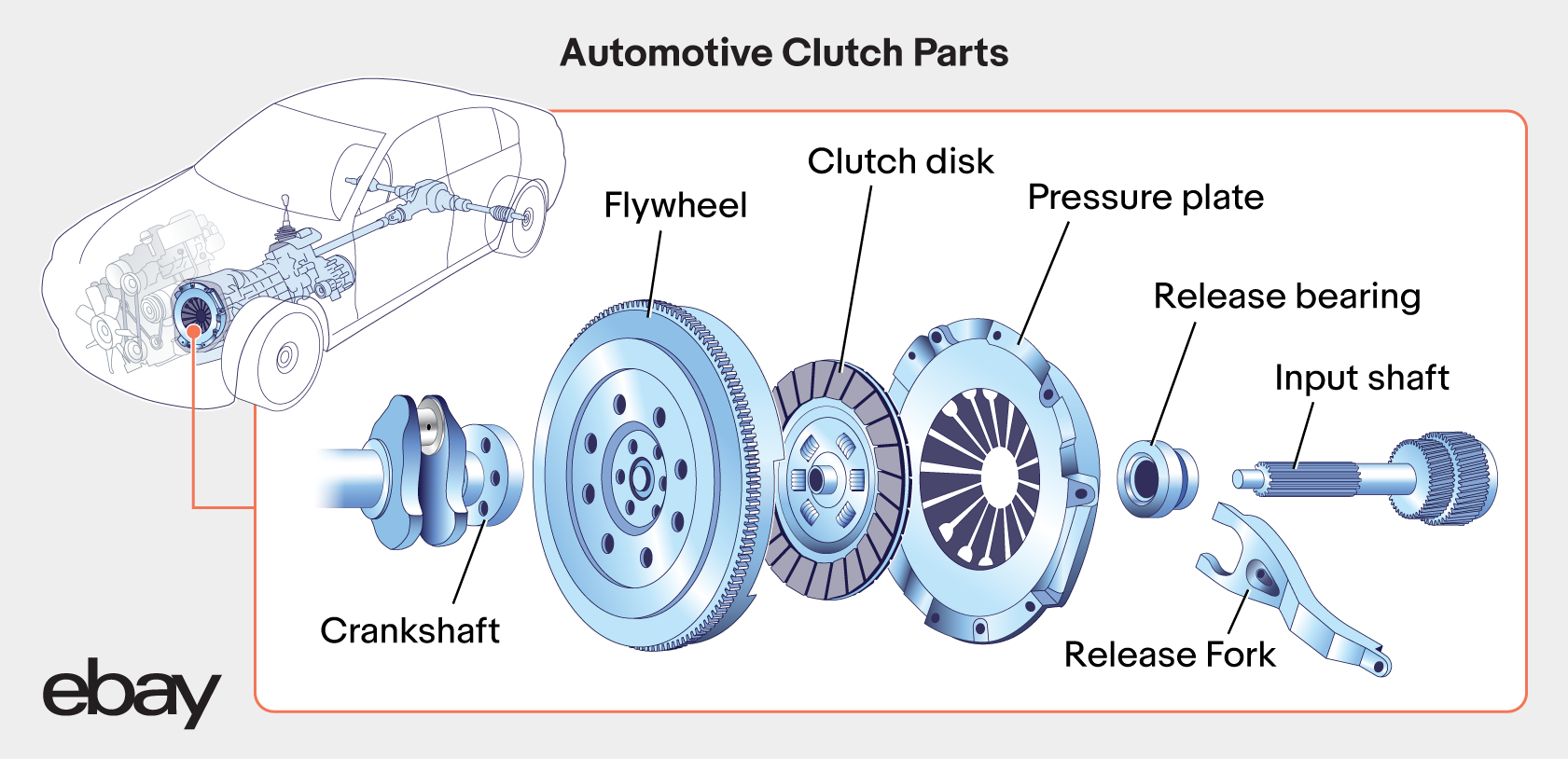

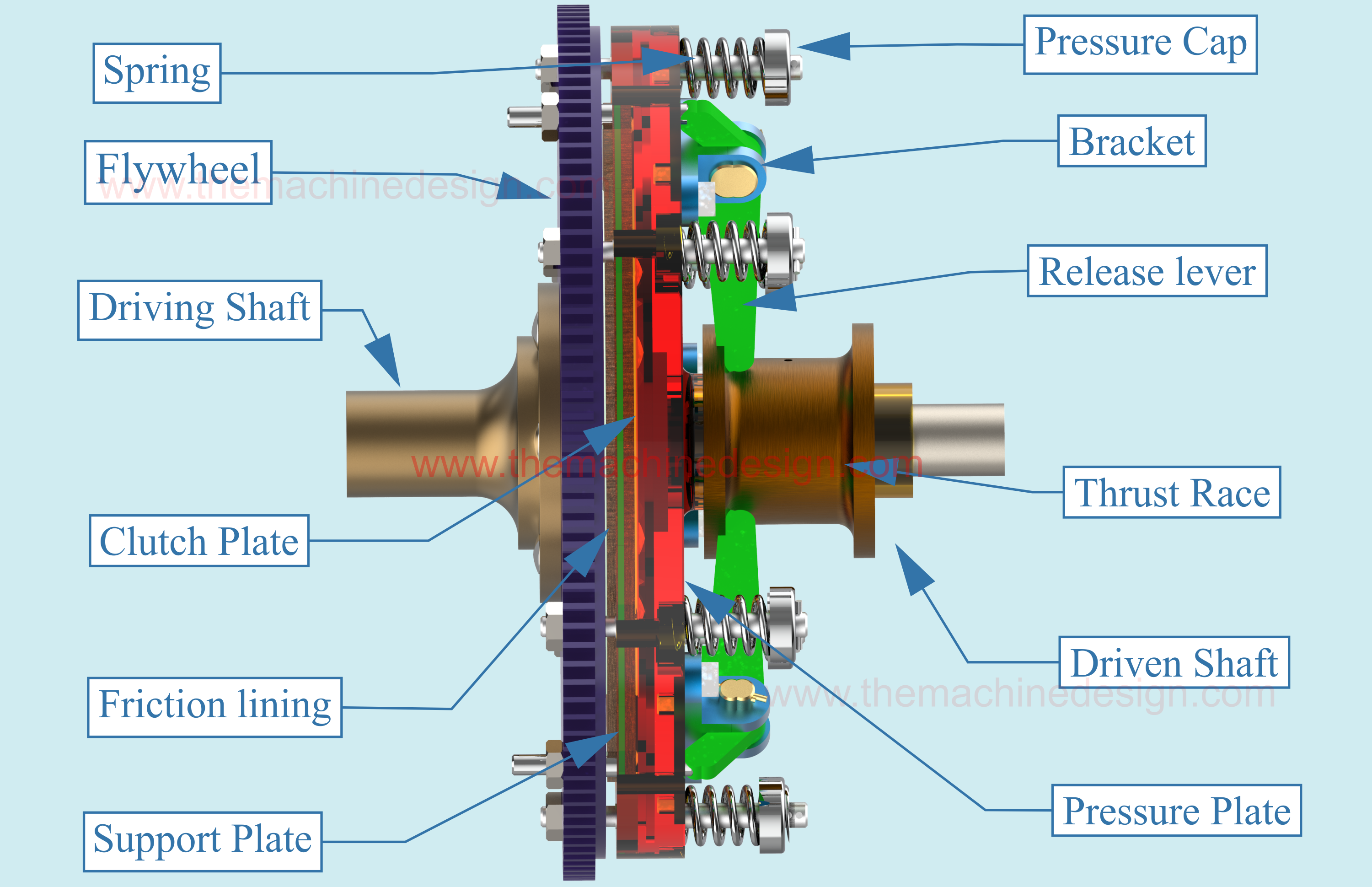

The clutch assembly diagram acts as a visual guide, detailing the components, their interactions, and their role in the vehicle’s overall operation. From the pressure plate to the release bearing, every element is depicted, allowing for a comprehensive understanding of the system’s inner workings.

Clutch Assembly Operation

The clutch assembly is a critical component in the powertrain of a vehicle, connecting the engine to the transmission. Its primary function is to enable the driver to engage and disengage the engine’s power from the transmission, allowing for smooth gear changes and vehicle control.

Clutch Engagement and Disengagement

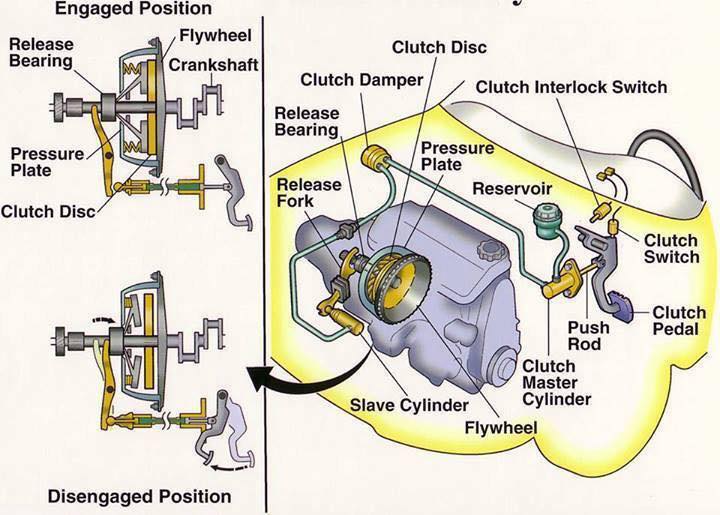

The clutch assembly facilitates the transfer of power from the engine to the transmission through a series of components working together. The process of engaging and disengaging the clutch involves the interaction of the clutch disc, pressure plate, and flywheel.

- Clutch Engagement:When the clutch pedal is released, the pressure plate is pushed against the clutch disc by hydraulic pressure or a cable system, clamping the disc to the flywheel. This connection allows the engine’s torque to be transferred to the transmission, enabling the vehicle to move.

- Clutch Disengagement:When the clutch pedal is depressed, hydraulic pressure or cable tension is released, allowing the pressure plate to move away from the clutch disc. This disconnects the engine from the transmission, allowing the driver to shift gears without stalling the engine.

Interaction with Transmission and Engine, 1992 xj clutch assembly diagram pdf

The clutch assembly acts as a bridge between the engine and the transmission. The flywheel, which is attached to the engine crankshaft, rotates at the engine’s speed. The clutch disc, sandwiched between the flywheel and pressure plate, is connected to the transmission input shaft.

- Engine Rotation:When the engine is running, the flywheel rotates, and the clutch disc rotates with it when the clutch is engaged.

- Transmission Input Shaft:The clutch disc is connected to the transmission input shaft, which transfers the rotational energy to the transmission gears.

Hydraulics or Cables in Clutch Operation

The method used to engage and disengage the clutch can vary depending on the vehicle.

Finding a 1992 XJ clutch assembly diagram PDF can be a real lifesaver when you’re tackling a clutch replacement. Understanding the components and their order is essential for a smooth job. It’s similar to how a diagram porsche boxster 1999 spark plug firing order can guide you in replacing spark plugs, ensuring proper ignition timing.

With the right diagram, even a complex task like replacing a clutch becomes manageable.

- Hydraulic Clutch Systems:In hydraulic systems, the clutch pedal is connected to a master cylinder that generates hydraulic pressure. This pressure is transmitted through a hydraulic line to a slave cylinder, which moves the pressure plate and engages or disengages the clutch.

- Cable Clutch Systems:In cable systems, the clutch pedal is connected to a cable that runs to the pressure plate. Depressing the clutch pedal pulls the cable, releasing the pressure plate and disengaging the clutch.

Common Clutch Assembly Problems

The 1992 XJ Cherokee clutch assembly, like any other mechanical component, is susceptible to wear and tear over time. Understanding common issues, their symptoms, and solutions can help you troubleshoot and maintain your vehicle effectively.

Clutch Pedal Feels Spongy or Goes to the Floor

A spongy or low clutch pedal can indicate several problems.

- Air in the Hydraulic System:Air trapped in the hydraulic lines can cause a spongy pedal feel. Air is compressible, which reduces the pressure needed to operate the clutch. This can be resolved by bleeding the hydraulic system.

- Low Clutch Fluid:A low fluid level can also lead to a spongy pedal. Check the fluid level in the master cylinder reservoir and top it off if necessary. Low fluid levels can be caused by leaks in the system.

- Worn Clutch Master Cylinder:The master cylinder is responsible for converting pedal pressure into hydraulic pressure. A worn master cylinder can leak fluid or fail to create sufficient pressure, resulting in a spongy pedal. Replacement is the only solution in this case.

- Worn Clutch Slave Cylinder:The slave cylinder pushes the clutch release bearing when you depress the pedal. A worn slave cylinder can leak fluid or fail to provide sufficient pressure, resulting in a spongy pedal. Replacement is the only solution in this case.

- Worn Clutch Disc:A worn clutch disc can lead to slipping, which can manifest as a spongy pedal. This is because the friction material on the disc is worn down, reducing the pressure needed to engage the clutch. Replacement is the only solution in this case.

Clutch Slipping

Clutch slippage occurs when the clutch disc cannot transfer enough power from the engine to the transmission. This can be caused by a number of factors:

- Worn Clutch Disc:As mentioned earlier, a worn clutch disc can cause slipping. The friction material on the disc wears down over time, reducing its ability to grip the flywheel.

- Contaminated Clutch Disc:Grease or oil contamination on the clutch disc can also cause slipping. The contaminants prevent the friction material from making proper contact with the flywheel.

- Worn Pressure Plate:The pressure plate clamps the clutch disc against the flywheel. A worn pressure plate may not be able to apply enough pressure, leading to slippage.

- Misadjusted Clutch Cable:If the clutch cable is too loose, it can cause slippage. Adjust the cable to ensure proper tension.

- Damaged Flywheel:A damaged flywheel can also contribute to clutch slippage.

Clutch Chattering or Noise

A chattering or noisy clutch can be caused by several issues:

- Worn Clutch Disc:A worn clutch disc can cause chattering, especially when the clutch is engaged or disengaged. The friction material on the disc can become uneven, causing the disc to vibrate.

- Worn Clutch Release Bearing:The release bearing rides on the pressure plate fingers and guides the clutch fork. A worn release bearing can cause noise, especially when the clutch is depressed.

- Damaged Flywheel:A damaged flywheel can cause chattering or noise. The flywheel is a heavy component that spins at engine speed. If it is damaged, it can vibrate, creating noise.

- Misaligned Clutch Assembly:A misaligned clutch assembly can also cause noise. If the clutch disc is not properly centered on the flywheel, it can vibrate, creating noise.

Clutch Pedal Sticks

A clutch pedal that sticks can be caused by several issues:

- Worn Clutch Master Cylinder:A worn master cylinder can cause the clutch pedal to stick. The piston inside the master cylinder can become stuck or worn, preventing the pedal from returning to its starting position.

- Worn Clutch Slave Cylinder:A worn slave cylinder can also cause the clutch pedal to stick. The piston inside the slave cylinder can become stuck or worn, preventing the clutch from disengaging properly.

- Seized Clutch Release Bearing:A seized clutch release bearing can prevent the clutch from disengaging properly, causing the pedal to stick.

- Sticky Clutch Cable:A sticky clutch cable can prevent the clutch from disengaging properly, causing the pedal to stick.

Clutch Assembly Replacement: 1992 Xj Clutch Assembly Diagram Pdf

Replacing the clutch assembly in a 1992 XJ is a relatively involved process that requires some mechanical expertise. It’s a good idea to familiarize yourself with the steps involved and the tools needed before attempting the replacement.

Tools and Materials Required

Before starting the replacement, gather all the necessary tools and materials. Here’s a list of essentials:

- Jack and jack stands

- Torque wrench

- Socket set

- Wrench set

- Pry bar

- Hammer

- Breaker bar

- New clutch assembly (including disc, pressure plate, throw-out bearing, and pilot bearing)

- Transmission fluid

- Grease

- Shop towels

- Safety glasses

- Work gloves

Safety Precautions

Safety should always be your top priority when working on your vehicle. Here are some essential precautions to take:

- Always use jack stands to support the vehicle when working underneath it.

- Wear safety glasses and work gloves to protect your eyes and hands.

- Be aware of moving parts and avoid contact with them.

- Use proper lifting techniques to avoid injury.

- Work in a well-ventilated area.

- Have a fire extinguisher readily available.

Clutch Assembly Replacement Steps

Here’s a step-by-step guide on how to replace the clutch assembly in your 1992 XJ:

- Prepare the Vehicle:

- Park the vehicle on a level surface and engage the parking brake.

- Disconnect the negative battery terminal.

- Raise the vehicle using a jack and secure it with jack stands.

- Remove the wheels from the front of the vehicle.

- Remove the Transmission:

- Remove the driveshaft from the rear differential.

- Disconnect the shifter linkage from the transmission.

- Disconnect the transmission cooler lines from the transmission.

- Remove the starter motor.

- Remove the transmission mount.

- Support the transmission with a transmission jack.

- Carefully lower the transmission from the engine.

- Replace the Clutch Assembly:

- Remove the old clutch disc, pressure plate, and throw-out bearing.

- Clean the flywheel thoroughly.

- Install the new clutch disc, ensuring the alignment is correct.

- Install the new pressure plate, tightening the bolts to the specified torque.

- Install the new throw-out bearing.

- Replace the pilot bearing if necessary.

- Reinstall the Transmission:

- Carefully lift the transmission back into place, aligning the input shaft with the flywheel.

- Reinstall the transmission mount and tighten the bolts.

- Reconnect the starter motor.

- Reconnect the transmission cooler lines.

- Reconnect the shifter linkage.

- Reinstall the driveshaft.

- Refill Transmission Fluid:

- Add transmission fluid to the transmission until the proper level is reached.

- Reassemble the Vehicle:

- Lower the vehicle and remove the jack stands.

- Reinstall the wheels.

- Reconnect the negative battery terminal.

- Test Drive:

- Start the engine and test drive the vehicle to ensure the clutch is functioning correctly.

Maintenance and Inspection

Keeping your 1992 XJ’s clutch in top shape requires a little TLC. This section will guide you through the recommended maintenance practices, how to spot signs of wear and tear, and the importance of regular fluid checks and adjustments.

Clutch Assembly Maintenance

Regular maintenance ensures your clutch performs reliably and lasts longer. Here are some key practices:

- Fluid Checks:The hydraulic system that operates your clutch relies on fluid. Regularly checking the fluid level and condition is essential. Low fluid levels can lead to clutch slippage, while contaminated fluid can cause damage to the system.

- Adjustments:Over time, the clutch linkage can wear, causing the clutch pedal to feel spongy or requiring more effort to engage. Adjusting the linkage restores proper pedal feel and ensures the clutch engages smoothly.

- Regular Inspections:A visual inspection of the clutch assembly is crucial. Look for signs of wear on the clutch disc, pressure plate, and throw-out bearing. Also, inspect the hydraulic lines for leaks and the clutch pedal for free movement.

Clutch Wear and Tear Inspection

Understanding how to inspect your clutch for wear and tear can help you identify problems before they become major issues. Here’s what to look for:

- Clutch Pedal Feel:A spongy or high pedal can indicate low fluid levels or air in the hydraulic system. A hard pedal might suggest worn-out clutch components.

- Clutch Slippage:If the engine revs up but the vehicle doesn’t accelerate, your clutch may be slipping. This is a sign of worn-out clutch plates or a problem with the pressure plate.

- Clutch Noise:Unusual noises during engagement or disengagement, such as grinding or rattling, indicate wear or damage to the throw-out bearing or other clutch components.

Fluid Checks and Adjustments

Regular fluid checks and adjustments are crucial for maintaining your clutch system’s health.

- Fluid Level Check:The fluid reservoir for the clutch hydraulic system is typically located near the master cylinder. Check the fluid level and ensure it’s within the recommended range. Low fluid levels can cause clutch slippage.

- Fluid Condition:Inspect the fluid for discoloration, contamination, or unusual smells. Contaminated fluid can damage the hydraulic system and should be replaced.

- Clutch Linkage Adjustment:If the clutch pedal feels spongy or requires excessive effort, the linkage may need adjustment. This process involves tightening or loosening the clutch cable or adjusting the linkage rod.

Troubleshooting and Diagnosis

Diagnosing clutch problems in your 1992 XJ can be a bit of a detective game, but with the right tools and knowledge, you can pinpoint the issue and get your Jeep back on the road. There are several common methods for diagnosing clutch problems, and we’ll explore them along with some helpful tips to help you identify specific issues.

Common Methods for Diagnosing Clutch Problems

Here are some common methods used to diagnose clutch problems:

- Visual Inspection:A thorough visual inspection can reveal obvious signs of wear and tear, such as a worn clutch disc, damaged pressure plate, or leaking hydraulic lines. Look for signs of fluid leaks, cracks, or excessive wear on components.

- Test Drive:Pay attention to how the clutch engages and disengages. Does it slip when accelerating? Is there a grinding noise when engaging? Does the pedal feel spongy or have a high engagement point? These symptoms can point to specific clutch problems.

- Clutch Pedal Feel:A spongy or low pedal can indicate air in the hydraulic system or a problem with the master cylinder. A high engagement point might mean the clutch disc is worn or the pressure plate is malfunctioning.

- Engine RPM:If the engine revs up while the vehicle is moving but the speed doesn’t increase, it’s a strong indicator of clutch slippage. This happens when the clutch disc isn’t gripping the flywheel properly.

- Noise:Grinding noises during engagement or disengagement usually indicate worn clutch components, such as the release bearing or the clutch disc itself. A rattling noise might point to a problem with the pressure plate or flywheel.

Clutch Troubleshooting Flowchart

Here’s a simplified flowchart to guide you through troubleshooting your clutch:

Start:Clutch Problem Detected ->Visual Inspection: Obvious Damage? Yes:Replace Damaged Components No:Proceed to Next Step ->Test Drive: Clutch Slipping? Yes:Check Clutch Disc and Pressure Plate No:Proceed to Next Step ->Clutch Pedal Feel: Spongy or Low?

Yes:Check Hydraulic System and Master Cylinder No:Proceed to Next Step ->Noise: Grinding or Rattling? Yes:Inspect Release Bearing, Clutch Disc, and Pressure Plate No:Further Investigation Needed (Professional Assistance May Be Required)

Identifying Specific Clutch Issues

Understanding the common symptoms associated with specific clutch problems can help you narrow down the issue. Here are some key indicators:

- Clutch Slipping:This usually points to a worn clutch disc, a faulty pressure plate, or a problem with the hydraulic system.

- Clutch Engagement Problems:A high engagement point or a rough engagement can be caused by a worn clutch disc, a damaged pressure plate, or a problem with the release bearing.

- Clutch Pedal Problems:A spongy or low pedal often indicates air in the hydraulic system or a faulty master cylinder. A stiff or high pedal could signal a problem with the slave cylinder or a worn clutch disc.

- Noise:Grinding noises during engagement or disengagement typically indicate worn clutch components, such as the release bearing or the clutch disc. A rattling noise might be caused by a faulty pressure plate or flywheel.

Alternative Clutch Systems

The standard clutch system, found in many vehicles, utilizes a mechanical linkage to connect and disconnect the engine from the transmission. However, advancements in automotive technology have led to the development of alternative clutch systems that offer unique advantages.

Electro-Hydraulic Clutch Systems

Electro-hydraulic clutch systems are gaining popularity in modern vehicles. These systems replace the mechanical linkage with an electric motor and hydraulic actuator. The electric motor controls the hydraulic pressure that engages and disengages the clutch. This approach offers several benefits:* Improved Control and Precision:The electric motor allows for more precise control over clutch engagement and disengagement, resulting in smoother shifts and reduced wear on the clutch components.

Enhanced Fuel Efficiency

The system’s precise control enables smoother gear changes, minimizing power loss and contributing to better fuel economy.

Reduced Maintenance

Electro-hydraulic systems often require less maintenance compared to traditional mechanical systems.Examples of vehicles with electro-hydraulic clutch systems include:* Porsche PDK (Dual Clutch Transmission):The PDK transmission utilizes two separate clutches to manage gear changes, providing lightning-fast shifts and smooth acceleration.

Audi S-Tronic

Similar to the PDK, Audi’s S-Tronic transmission employs dual clutches for rapid and efficient gear changes.

Automated Manual Transmissions (AMTs)

AMTs, also known as robotized manual transmissions, combine the efficiency of a manual gearbox with the convenience of an automatic transmission. These systems utilize a computer-controlled actuator to engage and disengage the clutch, automating the shifting process.* Cost-Effectiveness:AMTs are typically less expensive to manufacture than traditional automatic transmissions, making them a more budget-friendly option.

Fuel Efficiency

AMTs, due to their manual gearbox design, can achieve better fuel efficiency than some automatic transmissions.

Smooth Shifting

Modern AMTs have advanced software and actuators that provide smoother shifting than earlier generations.Examples of vehicles with AMT systems include:* Tata Nano:This popular Indian hatchback uses an AMT to provide an affordable and convenient driving experience.

Renault Kwid

The Kwid, another popular entry-level hatchback, offers an AMT option for customers seeking an automatic transmission without the premium price.

Dry Clutch Systems

Dry clutch systems, commonly found in motorcycles, utilize a dry clutch plate that engages and disengages directly with the engine’s flywheel. These systems offer advantages in terms of:* Quick Response:Dry clutches provide a faster response time compared to wet clutches, offering a more engaging driving experience.

High Torque Capacity

Dry clutches are capable of handling higher torque levels, making them suitable for high-performance applications.Examples of vehicles with dry clutch systems include:* Ducati Panigale:This high-performance motorcycle utilizes a dry clutch for its aggressive performance and quick response.

Honda CBR1000RR

The CBR1000RR, another high-performance motorcycle, features a dry clutch system to deliver a thrilling riding experience.

Wet Clutch Systems

Wet clutch systems, commonly used in cars and some motorcycles, utilize a clutch plate that operates in an oil bath. This design offers:* Reduced Wear:The oil bath provides lubrication and cooling, minimizing wear on the clutch components.

Smooth Engagement

Wet clutches offer a smoother engagement than dry clutches, contributing to a more comfortable driving experience.

Quiet Operation

The oil bath reduces noise and vibration, resulting in a quieter operation.Examples of vehicles with wet clutch systems include:* Toyota Corolla:The Corolla, a popular compact car, uses a wet clutch system for its automatic transmission.

Harley-Davidson Sportster

This classic cruiser motorcycle utilizes a wet clutch system for its smooth and reliable operation.

Resources and Further Information

Beyond the information provided in this guide, there are numerous resources available to delve deeper into the intricacies of 1992 XJ Cherokee clutch assemblies. These resources can provide you with valuable insights, detailed technical specifications, and troubleshooting tips.

Online Resources and Technical Manuals

The internet is a treasure trove of information, offering access to a wide array of resources on 1992 XJ Cherokee clutch assemblies. You can find technical manuals, repair guides, and forums dedicated to this specific vehicle model.

- Cherokee Forum: This online community is a great resource for finding answers to specific questions about your 1992 XJ Cherokee clutch assembly. You can connect with other enthusiasts, share experiences, and get expert advice.

- AllDataDIY: This website offers access to a comprehensive database of repair manuals, including information on clutch assemblies. They provide detailed instructions and diagrams to assist with repairs and maintenance.

- Factory Service Manuals: These manuals, often available online or through specialized automotive retailers, offer the most detailed information on the 1992 XJ Cherokee clutch assembly. They provide detailed instructions for every aspect of the assembly, from removal and installation to troubleshooting and repair.

Query Resolution

Where can I find a 1992 XJ Clutch Assembly Diagram PDF?

You can find a 1992 XJ Clutch Assembly Diagram PDF online through various sources such as automotive repair manuals, online forums, or by contacting your local Jeep dealership.

What is the difference between a hydraulic and cable-operated clutch system?

A hydraulic clutch system uses fluid pressure to engage and disengage the clutch, while a cable-operated system uses a cable connected to the clutch pedal. Hydraulic systems generally offer smoother engagement and require less pedal effort.

What are the signs of a failing clutch assembly?

Signs of a failing clutch assembly include slipping when accelerating, difficulty shifting gears, a grinding noise when engaging the clutch, and a burning smell.